Piglet Trespassers William

-

Posts

46 -

Joined

-

Last visited

Never

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Piglet Trespassers William

-

-

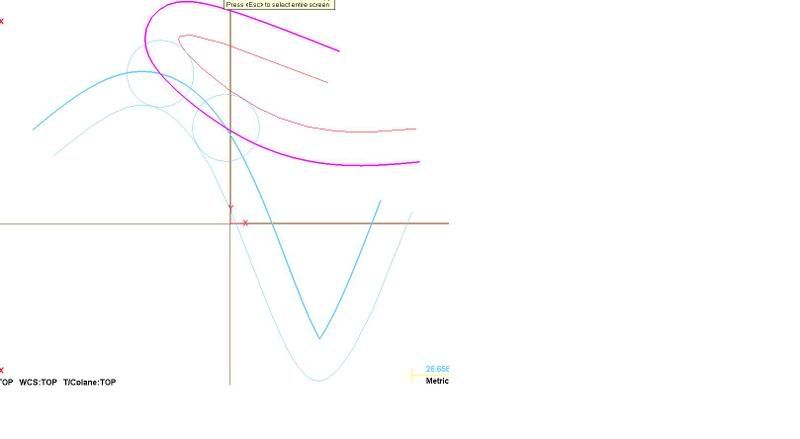

Arc tangent to two splines with given radius ,using xform-offset contour

-

The Price of Freedom

My good friend the Bird of Freedom

Killed like mindless stupid chicken

Destiny that makes me moaning

Every morning I`m weeping

Some of you prefer it roasted

Others like it chopped and baked

Others like it hot and spicy

There`s no end for human hatred

My turn next to loose the weighting

Soon I will be coloured pinky

Nicely cured fatty porky

Covered good with salt and pepper

-

I `ve seen it before ,not in this version

Ramsaver helped me

-

Could be worse, you could be under Hillary

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

This is personal offence

-

Create solid from one surface

Then use solid thicken

-

dont ever make me a moderator... I would have banned your xxxx from that.

~~~~~~~~~~~~

+1000

-

Personally I can not get it - >how come that everyone here makes good money using Mastercam

except Anubis .

I do not say it has no issues .

Every program has

His approach reminds me one of Mr Banquer .

Kinda waiting for ideal tool capable of everything .

Boy ,in this case who will need you ?

-

For the type of work I have 1 gig is nothing .

And if I open simultaneously more than one Mastercam ?

~~~~~~~~~~~

Based on my test I think 4Gb of ram might be a little overkill for the average user.

~~~~~~~~~~

Not at all .

Your can have small toolpathes but huge models

with lots of solids ,surfaces ,splines and etc .

In such a case to open couple of Mastercams with little memory is an invitation for crash

-

What other information do you experienced programmers keep close by that you refer to often?

~~~~~~~~~

15 years of machining experience

It gives me prediction close to real

machining parameters

-

Takashi !

You`ve done the excelent job !

Thank you very much !

-

I would do nothing do nothing .

I will make operatiom library for the first 4 toolpaths

and will import operations with geometry

-

Thank you very much !!!!!!!!!!!!!!!!!!!!!!

Works great

PS I like your Backspace idea

-

Thank you very much ,Mr Takashi Sato from Ai Solutions.

It is a pity ,though ,that I can use only top cplane ????

Being 4-5 axes programmer it makes this c-hook almoust useless

With great respect and best regards ,

Piglet Trespassers William

-

Axela .

You do too much for simple couple of mill movements

I mean I want to be fast .

And I don`t want to create anything

I want to do a thing that other programs have been doing for ages .

-

Well .I tested it .Looks good .

I have something similar from early 1990 `s and still use it .

You need preview to turn your program into something useful

-

Why not ?

-

I don`t consider it to be enhancement.

It turns MC more dangerous

Like you ever had need to delete level at all ?

-

Welcome on board .

What version of Mastercam ?

-

I use pyramide cutters for 10 years ,at least ,on every material including hardened steel on stamps ,molds and general engraving when taper angle is less than 30 degrees with huge success .

You can make it 3,4,or 6 edges .

I used to grind them myself from broken end mills .

~~~~~~~~~~~~

You ever make pointed carbide engraving cutters by just grinding angles and having them come to a sharp point so the cutting angle is about 15 degrees

~~~~~~~~~~~

I prefer to take off small relief angle on the sharp point against one of angles to turn sharp point to small cuttting diameter .

The cutter becomes stronger

I usually measure it on microscope to get correct results

-

yOU are digging the trap for yourself

|Whoever tried once can not stop ever after

-

fILE SAVE ASCII

-

Is it was revolved surface ?

I saw lots of bugs with revolved surfaces mirrored both by xform ->mirror or transfrorm toolpathes like milling to the inside of the surface

If so recreate it as ruled

make analize->surfaces->set normals .

And you`ll be fine

-

I have done such things bu thousands and your technological approach is radically wrong .

I would use solid rough will for alluminium

3 flutes dia 12-14 mm for every rough cut

At first stage I would first make 2 sides in y direction while

electrode still rigid

I would go conventional if it is rigid less than I expect .

I would go S2000 F500 MM/MIN FOR END MILL 12 MM .

Next I would make upper finish after roughing it

I would use ball mill 3 mm .

Take note the rib is wstill rigid

Now I would rough and finish one of the tapered walls

I would use ball mill 14 mm for finish all directions conventional

And than the last side .

Think about it and you will see my technology is bullet-proof

-

You are welcome ,5kax !

4-5axis gear hobbing

in Industrial Forum

Posted

Just remember that trunion uses rubber belts to drive the axis. I know for a fact that you can damage that belt and scrap parts.

~~~~~~~~~~~~~~~~~~~~~~

+1000

Was personally shocked to see the ins of Haas trunion 210

Pathetic !