veritasproject

-

Posts

77 -

Joined

-

Last visited

Never

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by veritasproject

-

-

Hi,

when i post out a 4th axis move and there is a change in the direction it needs to cut like i zig zag move over a radius all the a moves are + when it should be changing form + to - and back again Help!!!

the tool path is a 5x swart ( lock into 4 axis ) using X4 and MPmaster Post

-

i would like to say thank you to all of you out there for you help

-

i was just handed my walking papers do to the fact that the division i was working for out in China is going under.

so here it is

i am 5 axis programmer

i am proficient in x2 and x3

okuma, fadal, and fanuc mill set up

4 years exparince

if you know of any company's in so cal looking for

some one please let me know.

thank you all for your help

-

yes its a quadro fx 3700

-

i have a nvidai 3700 video card and i dont run solidworks is the solidworks driver still the best driver for master cam?

-

Robert

just need to do it right and it will be ok

-

this is what it looks like and what i need is g code

WNo.200902 ( PK009-OP2(2) )

UNo.MAT OD-MAX ID-MIN LENGTH RPM FIN-X FIN-Z WORK FACE

0ぃ葵 18. 0. 80. 1500 0.08 0.04 3.

UNo.UNIT # 1 # 2 # 3 # 4 # 5 # 6 # 7 # 8 # 9 #10 #11 #12

1 M 8

UNo.UNIT RV FV R-FEED R-DEP. R-TOOL F-TOOL

2EDG FCE 79 99 0.06 0.3 11

SEQ SPT-X SPT-Z FPT-X FPT-Z RGH

1 12. 0.3 0. 0.

UNo.UNIT # DIA DEP-1 DEP-2 DEP-3 C-SP FEED TOOL

3DRL FCE 1 2.5 2.5 1.5 1. 11 0.03 1

SEQ SPT-Z FPT-Z

1 0. 2.

UNo.UNIT # CPT-X CPT-Z RV FV R-FEED R-DEP. R-TOOL F-TOOL

4BAR OUT 0 12. 0. 88 90 0.08 0.3 11

SEQ SHP S-CNR SPT-X SPT-Z FPT-X FPT-Z F-CNR/$ RADIUS/th. RGH

1ar1 7.925 0. 9.356 0.413 0.826 0.05

2CTR @ 7.925 0.826 @ @ @ R U

3TPR 9.356 0.413 9o833 0.826 R 0.127 30. 0.05

4TPR 10.82 0.826 11.405 1.119 45. 0.03

UNo.UNIT # CPT-X CPT-Z RV FV R-FEED R-DEP. R-TOOL F-TOOL

5BAR OUT 0 12. 0. 88 90 0.12 0.3 2

SEQ SHP S-CNR SPT-X SPT-Z FPT-X FPT-Z F-CNR/$ RADIUS/th. RGH

1ar1 7.925 0. 9.356 0.413 0.826 0.05

2CTR @ 7.925 0.826 @ @ @ R U

3TPR 9.356 0.413 9o833 0.826 R 0.127 30. 0.05

4TPR 10.82 0.826 11.306 1.069 45. 0.03

5TPR 11.306 1.069 11.573 1.3 30. 0.03

UNo.UNIT # DIA DEP-1 DEP-2 DEP-3 C-SP FEED TOOL

6DRL FCE 1 4.3 2. 1.5 1. 11 0.05 12

SEQ SPT-Z FPT-Z

1 0. 42.

UNo.UNIT CHANGE-PT GEAR TOOL

7MNP 1 1 12

SEQ G DATA-1 DATA-2 DATA-3 RADIUS/VARIABLE RPM FEED M OFS

1 0

UNo.UNIT # CPT-X CPT-Z RV FV R-FEED R-DEP. R-TOOL F-TOOL

8BAR IN 0 4.3 0. 80 85 0.06 0.2 6 6

SEQ SHP S-CNR SPT-X SPT-Z FPT-X FPT-Z F-CNR/$ RADIUS/th. RGH

1ar1 7.925 0. 6.757 0.242 0.826 0.05

2CTR @ 7.925 0.826 @ @ @ R D

3TPR 6.757 0.242 4.3 1.47 45. 0.05

UNo.UNIT # DIA DEP-1 DEP-2 DEP-3 C-SP FEED TOOL

+ 9DRL FCE 4 4.5 3. 3. 3. 11 0.04 10

SEQ SPT-Z FPT-Z

1 0. 79.

UNo.UNIT CHANGE-PT GEAR TOOL

10MNP 1 1 10

SEQ G DATA-1 DATA-2 DATA-3 RADIUS/VARIABLE RPM FEED M OFS

1 0

UNo.UNIT # DIA DEP-1 DEP-2 DEP-3 C-SP FEED TOOL

+11DRL FCE 3 4.5 @ @ @ 12 0.03 8

SEQ SPT-Z FPT-Z

1 0. 79.

UNo.UNIT CHANGE-PT GEAR TOOL

12MNP 1 1 8

SEQ G DATA-1 DATA-2 DATA-3 RADIUS/VARIABLE RPM FEED M OFS

1 0

UNo.UNIT # CPT-X CPT-Z RV FV R-FEED R-DEP. R-TOOL F-TOOL

13BAR OUT 0 11.5 0. 88 36 0.03 0.2 7

SEQ SHP S-CNR SPT-X SPT-Z FPT-X FPT-Z F-CNR/$ RADIUS/th. RGH

1LIN @ @ 7. 0. @ 0.03

2ar1 7.925 0. 9.356 0.413 0.826 0.03

3CTR @ 7.925 0.826 @ @ @

4TPR 9.356 0.413 9o833 0.826 30. 0.03

5LIN @ @ 11.5 0.826 @ 0.03

UNo.UNIT # CPT-X CPT-Z RV FV R-FEED R-DEP. R-TOOL F-TOOL

+14BAR OUT 0 11.5 0. 88 36 0.03 0.2 7 A

SEQ SHP S-CNR SPT-X SPT-Z FPT-X FPT-Z F-CNR/$ RADIUS/th. RGH

1LIN @ @ 7. 0. @ 0.03

2ar1 7.925 0. 9.093 0.242 0.826 0.03

3CTR @ 7.925 0.826 @ @ @

4TPR 9.093 0.242 11.349 1.37 45. 0.03

5TPR 11.349 1.37 11.5 1.5 0.03

UNo.UNIT COUNTER RETURN WK.No. CONT. NUM. SHIFT

15END 0 1 200901 0

-

dose any one out there know where i can find out how to change mazatrol code to gcode

i have a nc file in mazatrol that was sent to me from our china plant and i can make heads or tails of it . any help would be great

-

make a new wcs for the new zero and go to edit selected operations/edit common parameters then go to the planes and change it to the new wcs

then update your z depths in all your toolpaths

-

where are you located? ntma in ca has some advanced class for mastercam

-

dose any one know of a roller burnish manufacturers in the usa i just cant find one on the web

dose any one know of a roller burnish manufacturers in the usa i just cant find one on the web

-

i am sorry at my new company i do not have a 5x set

but just play with it and you will get. and did you draw your custom tool?

-

i would try a swarf toolpath and set the normals the right way

-

i tried to open you fpt file and it is not the right format or some thing is it an x3 file?

-

Can any one help me i am new to turning steel. i looked online for feeds and speeds and was unable to find anything. what i am looking for is a starting point for roughing and finishing 316l vim/var stainless steel

thank you

-

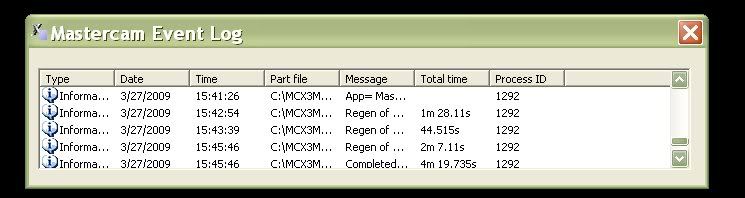

old work station time was 23.50 mins

new work stations

nvidia quadro fx 3700

intel quad core 3.00ghz

4g ram

this is so cool

-

it is a newer mpmaster post but i can not find the line to trun this option on or off

-

i have a program that i am run on a 4th axis and and for each position i have a new work cord g15 h1 for a0. h2 for a90. and so on but before every change of work cord it post out a g30 p1 how can i turn this off? is it in the post or machine def ?

i looked in the machine def and could not find any thig for this

i looked in the machine def and could not find any thig for this -

it dose not work on my pc

-

i do alot of 3d and 4th axis. 5axis sometimes

-

i am looking at getting a new work staition and i dont know which video card to get out of this to

512MB PCIe x16 nVidia Quadro FX3700, Dual Monitor DVI Capable

or

512MB PCIe x16 nVidia Quadro FX1700, Dual Monitor DVI Capable

is the quardro fx3700 over kill?

-

quote:This will turn all the Windoze eye candy off

thank you this help some but it looks like i will be stuck with this slow pc for some time

and thank you all for the video card suggestion

but my pc only saports P.C.I. card Not P.C.I.e. or any other

-

looking for and new pc.i want to run mastercam x3 with out any problems

-

ii just spock to the repesentative and it would seem that she did not know very much about run mastercam all she could do was tell me the min. specs for it to run and then she just pawnd me off on the i.t. guy who i should upgrade to a new workstaition

4th axis post help

in Industrial Forum

Posted

It is set to index the shortest distance