-

Posts

1,255 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Joe788

-

-

We've replaced 4 NMV3000's in the last year with MAM72-35V's. There is NO comparison between the two. More will fall to Matsuura.

Technically you've only replaced 1, at darmark, since Warmelin still has both of theirs (even though they added a MAM). Mori sold more NMV3000s in the time they've existed, than Matsuura has sold 35Vs in that same time. I hardly think 3 for sale by two users is a solid condemnation. Just a little food for thought

.gif)

That said, I'd take a MAM72-35V over an NMV every day that ends with a Y. Great theoretical engineering doesn't always lead to great real world results, as Mori's "octagonal ram" and "DCG" attest.

-

I found the rankings listed here quite interesting.

I have no idea if they are complete hogwash or not.

Keep in mind that they are based on revenue and not units sold.

In order.

Trumpf

(Germany)

Shenyang Group

(China)

Amada

(Japan)

DMTG

(China)

Komatsu

(Japan)

DMG Mori Seiki Co. Ltd.

(Japan)

DMG Mori Seiki AG

(Germany)

Schuler

(Germany)

Jtekt

(Japan)

Okuma

(Japan)

MAG

(U.S./Germany)

Makino

(Japan)

Doosan Infracore

(South Korea)

Haas

(U.S.)

GF Mach'g Solutions

(Switzerland)

http://www.statista.com/statistics/270234/largest-machine-tool-manufacturers-based-on-revenue/

^That site harvested those from the Metalworking Insiders Report Scorecard. Some of the private companies, like Mazak, don't report anymore. Mazak, Mitsui, Matsuura, and some others haven't reported in 5 years or so :

You can see the whole list here:

http://www.metalworkinginsider.info/?event=scoreboard

The most fascinating thing is how tiny the machine tool market really is compared to other industries. There are people right here on the forum who work at machine shops that have higher revenue than well known brands like Mitsui Seiki, Fidia, Kuraki, etc.

-

Unfortunately I don't have his number. It's been a decade since I've been in Niigata purgatory. I do know he is still active, and he is very good. Linkedin is probably your best bet at contacting him, or maybe call the socal Niigata dealer (whoever it is this week) and ask if they have it floating around? If there's any positive thing about Niigata (aside from the beefcake machines), it's that they didn't make very many different machine models, so a good guy that's been working on them for 20 years has seen everything.

-

Looking for some good contact info for a very capable repair guy.

TIA

What year is the machine, and what's wrong with it? (I probably can't help, but I just feel like re-living some old nightmares).

This guy is the bomb, and travels all over:

-

I am pretty sure this will be no help, but I would just hand it to the EDM guy..

^This. You could probably get an EDM guy to wire it for less than that 8" saw cost. Although, if you have 1000 to do, gonna need to figure out the saw.

Worst case scenario if wire isn't an option - use your existing saw to cut every other slot. Then fill them in with a low melting point metal, and cut the rest of the slots.

-

Easy to solve, you just need to decide if you want to make the change in the tool setter, or the spindle probe. I don't have any Blum anything, so I don't know how you'd do it on that end. But if you just want the spindle probe to match: face off a part with a tool you just set on the tool setter, then run the 9801 calibration macro for the spindle probe, measuring on that surface.

Or skip all that, and just add/subtract .0015 to the tool length of the probe in your tool offset register and call it a day.

-

Since you're looking at the lower end, check out YCM as well. No opinion on their double column machines, but a buddy of mine has a bunch of their 40x20 verticals and loves them.

http://www.ycmcnc.com/english/01_products/01_list.php?cid=2&id=22

-

Well, after a hand full of missing parts are delivered and a little clean-up I'll be ready to call the set-up technician

Funny thing was that he said this kinda thing (storage for extended period) happens more then you think with their waterJets. Maybe be up and cutting in three or so weeks.

If you have to work anywhere within 200 feet of that thing, you're really going to wish it was still sitting idle as a rat's home.

-

This endeavor is pretty much 99% contingent on Makino's willingness to support it.

^This. I haven't ever looked real close at the Makino matrix magazine, but I know Mazak and Toyoda have an entire standalone control that runs the magazine. So all of the logic and servos running the matrix magazine are independent from the machine's control. If Makino's matrix magazine works the same way, then integrating a different brand of magazine (the Cellro unit in particular) should be a slam dunk, since they should already have a parameter setup that passes off the needed data.

-

One of the pics says 'future high speed small part machining cell' !!!

That is one heck of an initial investment sat there.

Yeah it's an aerospace shop in socal. They have big bridge mills and whatnot. They had an old Mori SH-50 FMS that they replaced with those Toyodas. It's a different ball game when 630mm horizontals are the "small part cell". LOL

-

If the matrix system from MAM could be fully integrated and 99.99% reliable I think it could be a better system than Makino currently offers. Makino maxes out at 320 tools I believe and the cost of that system is ~$200k (guess). The MAM system starts at over 500 tools and is expandable to over 800. The IFs above are BIG ifs, but I will spend a considerable amount of time vetting these solutions to make sure they will actually work. Financially they are very viable however and well worth checking into. Two machines in a cell system with up to 1600 tools available between them would be really bad@ss!

How about we take a 90 degree turn - I bet you could snag this for less than those two magazines and an MMC are going to cost you. You'll need a new building though.

http://www.machinerynetwork.com/buy/detail.cfm?inventoryid=33728

-

I doubt you could ACTUALLY have it integrated, and working flawlessly enough to run an unmanned fms for under $200k

I can see adding a magazine to special standalone machine. But for a FMS?

Yeah I would guess the current pricing will be more like $200k. I was just saying if they could make it happen for $100k, they would sell a mountain of them.

I don't see any reason why the integration couldn't be rock solid bulletproof, as long as Makino and Fanuc will share all their little secret handshakes. (Mori had to strong-arm Fanuc by putting Mitsubishi controls on machines, before Fanuc would give them the keys to all the stuff they wanted to access with their MAPPS front end.)

-

Bob, did you place an order yet?

-

^Now that looks like a legitimate, viable option. It's fast enough that you can just throw away the existing 60 tool magazine, instead of trying to hodge podge some crap together where you have a robot trying to load and unload the existing pots. If they can sell that fully integrated for $100,000 - they'll have more customers than they know what to do with.

I think you have a snowball's chance in hell of getting Makino and Fanuc to give the integrator access to everything they need to implement it, but you never know until you try.

-

2

2

-

-

In all seriousness though I would just get another A51/61 w/ the 313 and keep your 2 a51's as stand alones when the time comes.

^This. Implement a bitchin RFID system with your two standalones. Then when the time comes, get another machine with the biggest magazine. You could still put one or both of your 60 tool machines into the cell, and just run jobs that have low tool counts and high volume. Makino's cell control will easily let you run a pallet across multiple machines, so you could just use the 60 tool machines to do all of the milling on a part, and then head over to the 313 tool machine for all the oddball size drills/taps/reamers/form tools etc.

-

1

1

-

-

I just searched Newegg for "Quadro", and then sorted by highest price first, and it came up with a zillion refurbished computers that seem to be spec-ed out pretty good.

For example:

Dell T7600 - 2 x E5-2640 - 32GB - 1 x 512GB SSD & 1 x 1TB - Quadro 6000

For $5000. Not bad when you consider a Quadro 6000 is $4300 on its own.

-

ALL of my computers are set up in RAID1, even the server. If a drive goes down it takes a few minutes to replace it. Otherwise it takes a fully day by the time all is said and done...

Did you buy the computer like that, or did you have somebody put it together?

-

5:45.879 using Ben's nifty time addition link. This is with the same computer I've had for a few years. It was in the low 40s on the old benchmark. It's an $800 Costco ZT Systems tower with a 128GB Samsung SSD, Windows 7 Pro, X8, a Quadro 4000, and nothing installed on it but SW and Mastercam. I've had a lot of computers over the years, and nothing has ever jumped out at me as a huge improvement the way the SSD did.

I want to get a new computer with a pair of SSDs in RAID1, but it seems like all the computer people I talk with think redundancy is dumb, and that it's way more fun to xxxx around with the computer for an entire day downloading updates, drivers, re-installing everything, etc after a crash - instead of spending an extra $250 on a redundant hard drive.

edit to add: When I changed from the Quadro FX570, to the Quadro 4000 a year ago, it made *no* noticeable difference in any way.

-

1

1

-

-

We're doing the same shopping right now. Not sure what the price list looks like in the other hemisphere, but up here the difference between the 80 tool magazine and the 120 tool magazine on the Variaxis is like $9,000 - so well worth the upgrade even if you don't think you need 120 tools.

-

1

1

-

-

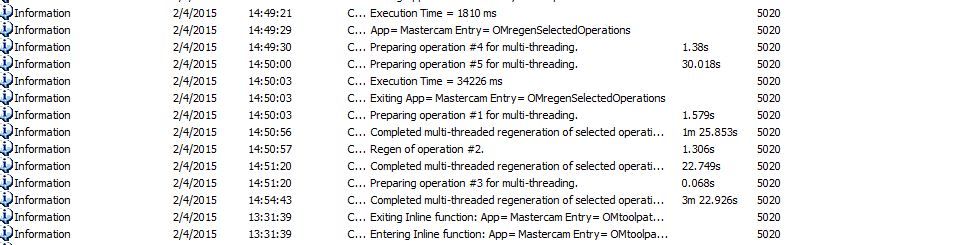

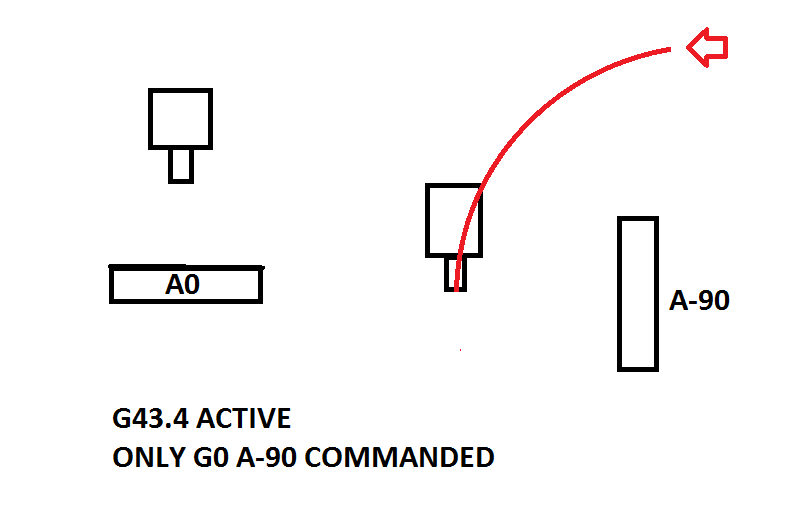

I'd be more concerned about why Vericut didn't show this ramming through the table with G43.4 active? G43.4 will move the XYZ in whatever direction they need to go, to keep the tool tip in the same place relative to the rotary axes, if no XYZ commands are issued with the rotary moves.

From A-90.855C265.745

To G00A-89.565C92.397

Here's an awesome drawing to explain what I mean. This is for the A axis, since that's easier to illustrate:

In your case, there was a C axis move commanded. So instead of 8 inches above the table, the tool tried to go 8 inches below it.

-

What presetter did you get, Bob? (Not that it matters to your question, I'm just curious).

-

Ron, what kind of machines are the Airflow systems units on?

-

Machine was rebuilt a few years ago. Don't know what the axis sounds like, they where in the process of moving the machine, it was used on cast parts, stainless, cast iron. As I mentioned, they where using this machine last week for making parts. We have the floor space, the only thing would be the cost of setting up the machine. We are currently inquiring on that.

The machine isn't necessarily garbage. It could serve you well for awhile, if you have the right work for it. I'd call Makino first and ask them some detailed questions about support. All of those mid 90's Makino MC98 and MC86 machines seem to always sell for basically scrap value, and I have to imagine there is a good reason for that.

-

LOL don't worry both of the companies Nick listed in his initial post have also been bought/sold/closed a few times as well.I have searched the internet for Metrolosys and Shadow Automation. Can't find either. Anyone know why?

Thanks

Mori Quality

in Machining, Tools, Cutting & Probing

Posted

I'm sure you're aware that machines have to go somewhere if they're replaced. And only one of those NMV-3000s in CA have gone anywhere other than the original owner. I could point you to three or four NMV3000 owners who would bet you 3/4 million dollars that the NMV is superior to the MAM. Would they be right? That's in the eye of the beholder, but the machines are certainly making good parts day in and day out.