-

Posts

135 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by RayD

-

-

Since X6, my very first operation is a Stock Model (referencing Stock setup/solid/stl if casting).

I do this even on simple programs, just to be able to toggle stock on/off without having to go into Machine Group Properties

-

Last few Large programs I did, I used a stock model that referenced an STL. This gave me the handy model in the Op manager, but i didn't have to deal with the regeneration time if I changed a minor setting in one of the operations that the Stock Model would have referanced.

I love stock model, but the regeneration time is slow on large/detailed paths. Much better in X7 than X6 but still has some shortcomings.

-

Bob,

Have you thought about outsourcing some of the programming? I know its not the best solution for your needs, but if it alleviates some of the workload sort term, may buy you some time to find the right guy to fill the role.

The High end guys your asking for are not easy to come by. they usually already have high paying jobs and are happy where they are.

-

free, opensource, easy to configure, supports web/mic input. Designed for streaming, but you can save as Mp4, or FLV.

http://www.techsmith.com/jing.html

Is good for short screen-capture videos, host built right into the software.

-

Have you run the Configuration from P+? It uses different Macros and variables than the supplied macros that come on the machine.

-

Each re-seller will be different, we add a bunch of stuff on top to "sweeten the pot" for maintenance costs.

http://www.inhousesolutions.com/products/mastercam/maintenance/

I do end-up doing a bunch of free onsite work at some customers, I am usually there for other issues and I get the "While your here can you show me this/that".

-

The 5 axis tutorial on emastercam is pretty decent, you have to be fairly proficient with mastercam, and the sample files are only to get the point of the exercise across. They show you how the settings work and when you would use each setting.

The real problem with 5axis is knowing when to use which path, and that comes with experience.

-

Thread-C Chook?

Although I have never tried it, but it could in theory work.

I have cut them manually programing with a button insert for the root, and I Profiled the OD/ID Shape with VNMG.

-

What error does the Haas throw? And what DNC software are you using?

Usually this is a an issue of the DNC pushing code in faster than the control can buffer it, or in your case it takes about an hour to reach this point.

You can try lowering the baud rate, or if your DNC software allows it put a delay between lines of code (1-3ms).

-

Windows 8 can cause problem's. Windows 7 is solid.

-

Heidenhain, powerful, and you already know it.

-

Thanks for the help guys. I've given up on the Lathe I'm nowd oing this part in the 5-axis mill

@Ray the RED surface is NOT square to the X-axis so your toolpath does not finish the part

Cheers Dave

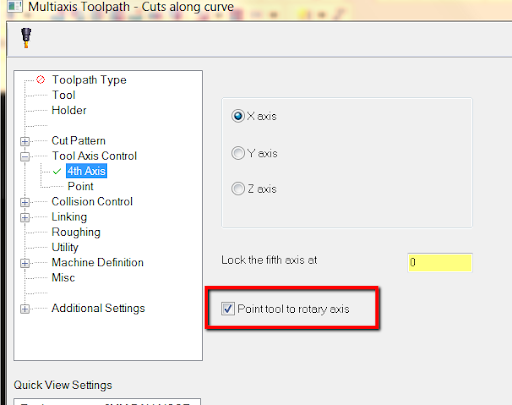

I never Claimed it did, I was showing how I would approach it and got no "y" moves(fast for removing material) as K2csq7 asked

.gif)

I'd Probably do a morph between 2 curves to finish the Rad portion(Red face)

-

No "Y" moves

Also how I would approach this part, much faster than rotating "C"

-

Make sure every path is a UNC path

Never ever use mapped drives in any network scenario unless making a shortcut for the desktop user

-

Try

External program number search

0 = disabled

1 = enabled

#6080 = 1

-

Ray, did you try that?

I did before and it still gave Y axis output in the posted code......

Yes it gives Y moves, albeit small ones

-

-

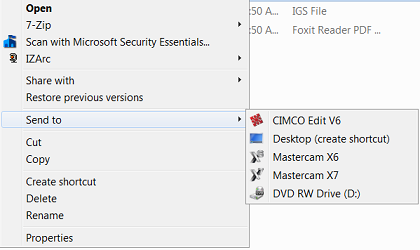

Another option is use the "Send To" Rightclick menu

To get to the SendTo folder, you’ll need to open up an Explorer window, and then paste in the following to the address bar

%APPDATA%\Microsoft\Windows\SendTo

Paste Shortucts for each application you want to use in that folder: Cimco, X6, X7, Notpad++, etc (You can also remove ones you don't use)

-

Talk to your reseller about Productivity+, its a software that runs inside of Mastercam where you can add Probe cycles inside of Mastercam, and manage them with your operations manager.

You can of course do this manually in your NC editor or with Manual Entry, but P+ streamlines the functions

http://mastercam.com/Products/Productivity/Default.aspx

-

cool trick, you can put a negative number in that field to over-cut

-

Rolldie if you don't have Multiaxis, if you have multiaxis available use it, Depending on the size of the slot/tool a simple Curve5 Path would work

-

Seems like everyone loves the cimco DNC solutions.. does it handle Ethernet and or FTP based transfer for newer controls? or is it only rs-232 based communications? I haven't ever had a chance to see it in use.

I have yet to find a Control I cant make work with Cimco DNC-Max

Serial, Directory Monitoring(Ethernet), FTP port, as well as a bunch of specialty protocols

-

I'm a big fan of highfeed cutters, but they are not always the most optimal. Try Optirest (looking at a stock model) with step-ups turned on, Start at full Flute height and step-up the walls, I would set the step-up to the maximum material your finish tool can handle.

Essentially the same thing your doing now, but from the bottom up

-

Position the Part in MCX like you would in the Machine, Use WCS from there. Or if in the 4th axis, just use Rotate Plane

As for What tool to use Dynamic WCS is the best, but I use whatever is handy, ie: if there is geometry or a solid face why reinvent the wheel, wcs bu geom/solidface etc.

Back Plot in Code Expert?

in Industrial Forum

Posted

In multichannel setup set your Machine as "User Defined"

"Channel Start" G13,G14,G15 (Use commas to add multipule codes)

If you check the "?" topleft corner in Cimco and Click on any field it will tell you what the field is used for and sometimes give an example.