Rocky16

-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Rocky16

-

-

This is my lathe with material 9310 steel hrc 38.

Can you give me some suggessions?

-

Thank you for your help. My customer gave me a screw to test. I start doing follow slavecam

-

I do not know how to lathe this spiral, can you help me?

Material 9310 steel hrc 36-42

-

1

1

-

-

I'm finally making the jump from X6 to X9.

Using X6, I could modify my mastercam.kmp file, mapping the regen, backplot, and verify buttons to hotkeys.

Does anyone know if there is a way to do this with X9?

How can you do it in X6?

-

OK, thank all of you, I am trying to do in some way.

-

Hi everybody,

I have a problem with my part, how can I erase the cutting air toolpath in this pic? I am using surface rough tool path, or which is the best toolpath in this case? Thanks

-

When verify for creating stock in next operation, you can use remove chips option to delete chips

https://photos.google.com/search/_tra_/photo/AF1QipNYru3rsEcd0_Zmm-3JiwWG1XBy9dju_OXz5mXP

-

-

And I am waiting another poem from Ted Bear then I will show how to lock these fields. it take 25 seconds to do that.

-

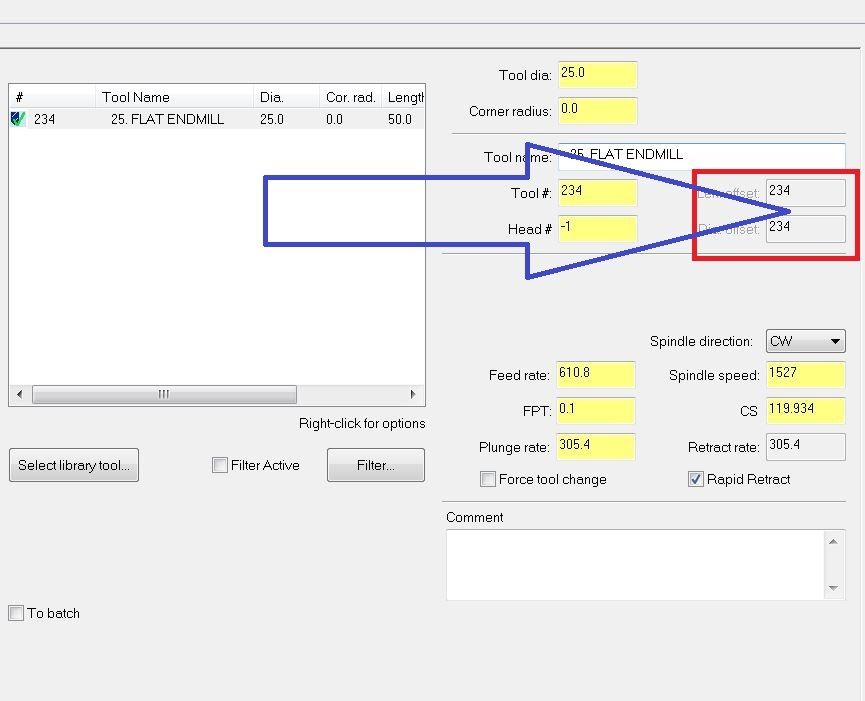

Ok I wrong but my 1/2" ball that's tool #5 today might be tool #7 tomorrow. I can't always use the same tool in the same slot. So once again, I'm changing tool #'s. Am I a total idiot for thinking this way?

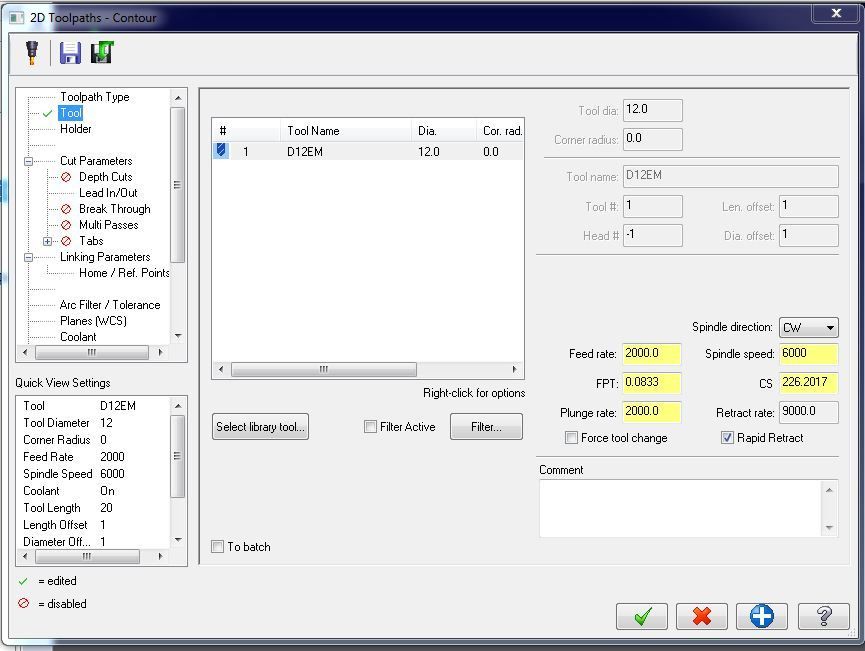

Hi,

Our shop floor use the same way like you, " 1/2" ball that's tool #5 today might be tool #7 tomorrowere. because we have many kind of parts with small quantity (1~5 pcs) and our machines run 24/24. There is no tool list satisfy for all parts so we change tool list everyday. this part needs 5 tools but the other needs 20 tools, it is impossible to setup a fix tool list on CNC machine (30 tools on tool magazine). When I execute NC code I always set the same number for tool number, length offset and dia offset ( for instance: T3, H3, D3)

Moreover, sometimes in the night shift, operators can use our mastercam program for editing something like change the dia of tool ( maybe replace dia 3/4" by 1/2" cause there is no new 3/4" ) or view the simulation or tool path. in order to avoiding input wrong parameters because careless, I like to lock this filed.

I never change or edit or check parameters in this filed, If I have to change or edit tool, I always using tool manager.

In a mastercam program may be you have more than 100 tool path so it is not good if you have to check parameters in this field. I think if you do not use it when you make a NC program, you should lock it.

-

How can I lock these fields in Mastercam? I know it can be lock but I dont know how to do.

Capture.JPG

Capture.JPGThank for helping.

HI, I am back. I can do this very easy.

And when you change your tool number, your leng and dia offset will be automatic change too. You will never worry about unintentional changing dia and leng offset in every command. So what do you think?

-

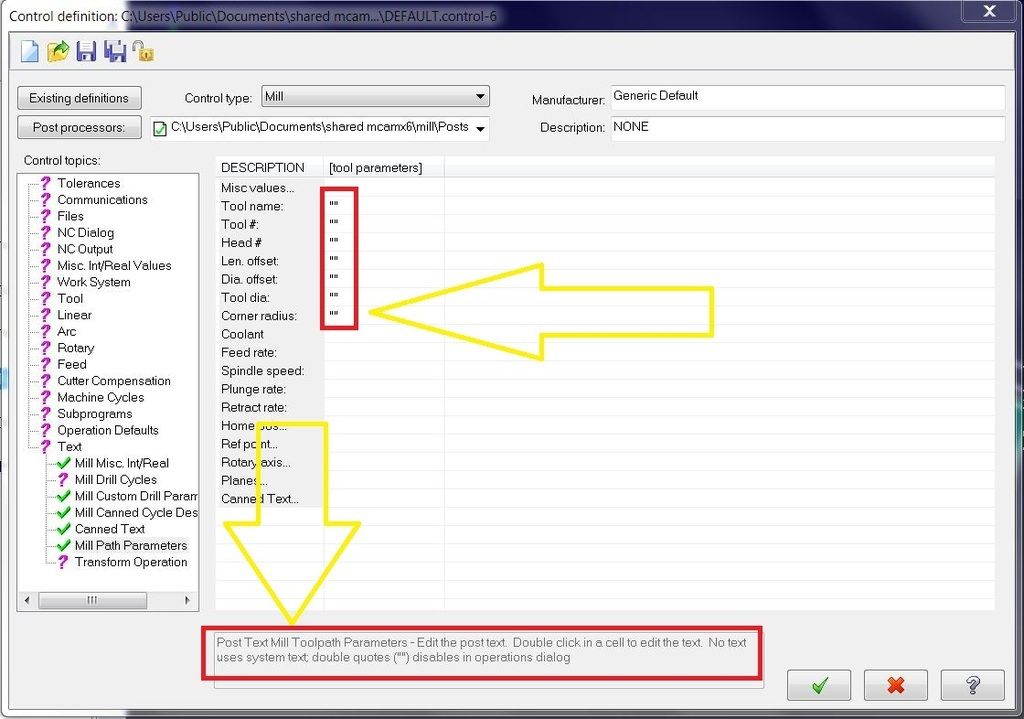

iN CONTROL DEFINITIONS IN TOOL SECTION SELECT ADD TO TOOL

length zero diameter zero

HTH

Thank for your reply. But I want tool number and head and dia and len. offset can not edit in the yellow box.

How can I turn it to gray box and it can not edit.

-

-

Ok I just mad more changes and cut the machining time down no STL used and removed one of your paths.

use this link to get the update. http://www.mastercam-cadcam.com/files/112a2511cadcam.zip

Many thanks for your help.

-

Thanks for help.

So I mean how to avoid air cutting tool path when I am using rough pocket or rough rest mill for op2. When i am making rough surface, I realize that tool have many air cutting. Tool cut the material has milled in OP1. Thank for your reading

-

Hi,

I have finished op1, I verified OP1 and save .stl file as stock for op2. I try to use stock for op2 as rough stock when I am using surface rough or surface rough rest mill. Anyone can help with it.

I am newbie in 5 axis, so if you have any idea to help my program look better, I am very thanks

https://www.dropbox.com/s/sc1n9wmou47iiqx/112A2511-4_16-1_CFEH.rar?dl=0

https://www.dropbox.com/s/tk429b5ryerq8ce/stock%20op2.rar?dl=0

-

1

1

-

X9 Backplot colors

in Industrial Forum

Posted

Did you do correct?

https://goo.gl/photos/x46uSDaR2oWbEDXx7

https://goo.gl/photos/YCSTwMBEUrGHTQds8