Steve Biehl - Cimquest Inc

-

Posts

1,386 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Steve Biehl - Cimquest Inc

-

-

Really no way to program tool motion in Mastercam with shaped tools that turret punch would have. You can't describe a rectangular tool and orient it to the shape you want to punch.

-

+1, needed to install new drivers for Pilot Pro to work in SW2010

-

when you did the reload, did you delete the install folders from the old install? If left, they would have the problem file(s) still there.

When you lost the tool bars, did an error box pop up when you launch MC?

-

Justin,

as a general tutorial, select geo, dynamic xform, snap gnomon to where you want origin, and now the biggie...

when you snapped the origin the function kicked out of the mode to attach the gnome. You need to press the icon on the bar back to gnomon manipulation and not geometry manipulation. Once back into the correct mode continue attaching gnomon to the geometry the way you want it. Then you can hit the buttons to move to wcs origin and wcs plane.

-

BBG, John is asking because we have seen the same problem with XP Home. Home is not supported but Mastercam will install and exhibit that symptom.

-

I hear ya Ron, but the old fastmode was easier, faster, and more controlable. It just should have been left in there along with the new debugger.

quote:I think that CNC Software made the right decision getting the post debugger in there, sure I sometime miss "fastmode" and I had hoped seeing a bigger improvement from X3 to X4, but if CNC Software will but some serious efforts into getting the debugger to work at a more acceptable level it would be a huge improvement.+1

Definitely need a real debugger. Always amazed me that CNC had no more then fastmode and a standard editor. Even for their own post debugging.

But again no need to kill 'fastmode' to get there.

-

Phil,

debugger runs fine on my Vista Business.

I don't really like the debugger, but no crashes.

I normally edit in a lot of literal outputs into my posts as I debug them. Really missing the 'fastmode' way of debugging.

-

what are your pc specs? what video card do you have?

-

rsm1722,

I checked out the 'Mastercam X Mill Training Tutorials' and Tutorial 4 doesn't have any surface creation. It is 'Level 1 - 2D TRANSFORM TOOLPATHS USING ROTATE & MIRROR'

Exactly what book are you using?

-

quote:"When are they going to release X4 ???" anyone, anyone?

when it's ready

-

Dave,

give me a call and I'll see what we can do.

quote:largest stranded gage availableheavier the gage the worse off you are. The large wire causes more resistance and will severely effect length you can communicate. A higher gage number is a smaller wire, so the highest gage would be right but not largest gage.

The Cimco wire we use is 28 gage.

-

echidna,

a couple things.

In Mastercam the axis the part should be in to get XZ lathe output is in the 'Top' plane. Which is really the XY plane of MC. So your lathe Z is MC X and lathe X is MC Y. You then can put MC in a D+Z+ plane to get the right axis display.

To put your part in the correct plane, use the Xform functions. You may need to do a combination of Rotates and Translates.

-

very nice Ron

-

there is a X3 Design LT, and Demo X3, both available from your reseller

-

Dell Precision M6400

Vista Business

2.54 GHz 4 GB

FX3700M video

-

just to wet your appetite for X4

X3 regen

X4 with Multi-Threading

The other thing is that after the 30 seconds of 'preparing...' I can go back to using Mastercam

-

George, give me a call in the office. Depending on what you need, I may be able to help

-

you could save a file as a template. prep it with the machine group and 2 toolpath groups.

-

axis sub is only correct if the center of the diameter is on the center of rotation.

-

had this problem with X3MU1 - 64bit

there is no mceval.dll with X3

CNC Tech Support steered me to registering the vbscript.dll in the windowssyswow64 folder.

thumbs up, works good now

-

Larry,

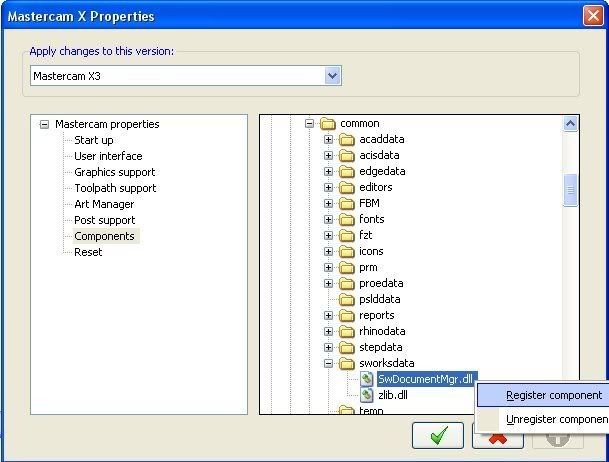

try registering the SW dll in Mastercam.

Go to Control Panel, run Mastercam X applet, go to Components and browse to Mastercam - 'common' - 'sworksdata' and right click SwDocumentMgr.dll and register component.

-

once the editor is running, can you open the nc file thru the normal, file - open function?

are you sure you can create a file in the location you are trying to write to?

-

Gordon, what doesn't work for the SMX? The old and new Prototrak are so close, it should be no issue

-

Peter, the generic Haas 5 axis is very good. If you need any adjustments to it just give me a call.

Setting up Makino FTP

in Industrial Forum

Posted

anyone have any experience setting up a Makino DUO64 with MGW-S6 control for FTP??

I have an issue with machine connecting to server for a folder share. Can't get the customers IT to get the user rights correct. So I'm attempting to setup FTP instead. Have the FTP settings entered into control but it still tries to connect to server and fails.

Thanks,

Steve