Alvaro Gil - Cimquest-inc.com

-

Posts

195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Alvaro Gil - Cimquest-inc.com

-

-

Just wanted to revive this old thread to say thanks! After two reboots, the search by file name started working for me also!

Just a note, with a dual stream machine you can only DNC to one control at a a time. The other stream must be run off the controller.Thanks, works great.

Post from Guest_CNC Apps Guy 1_* was awesome - just waht I needed.

-

Thank You Ernie. Life is good again! I was dreading doing a part in X8 without hole axis! Done in 3 seconds!

-

1

1

-

-

Hi, does anyone have any hints on how to import ports directly into mastercam? I can make a text file with hyperterminal or cimco edit and then import that, but I want to just click the output button on my cmm or optical comparitor and have them show up in mastercam directly.

Any help apreciated.

-

Get yourself an SSD. That will speed up just about everything!

-

Set Control def to break arcs @ 90 degrees and then post again. That will probably fix the problem. if it does not then it might be small arcs, set it to .002 and try again. If that does not do it then it is an error with arc check and tolerance.

Only do one change at a time. Post then check on machine. 90% of the time break arcs @ 90 deg will solve the issue.

-

Oh no. I'd say, try making all tools in the tool manager and not on the fly for now.

-

This happens when you are in an operation and you pick the same tool twice. For example, you make a contour opp, then select get tool and pick a .5" end mill. Then you make a finishing opp with another .5" end mill. Save file. Open file. corrupt tools.

The only work around I have found so far is to use the tool manager. Toolpaths-->Tool manager. Create the two tools. Create the toolpaths. Save. Open. Works.

Hope this helps somone. --

-

If the bolt holes are in a repeating pattern, use the Xform tollbooth, set to rotate and select tool pane method not coordinate. This will spit out a rotation code.

-

Ok, finaly got it working!

Here is what I had to do:

1 - Download MS VS 2010

2 - Download the MS VS 2010 SP1 update

3 - Uninstall the mastercam SDK (a repair does not cut it!)

4 - Install the mastercam SDK for X6 MU2

The C-Hook wizard now shows up under new project -> C++

-

I just tried updating to SP1 then running a repair on the SDK... When I create a new project, there is still no mastercam section under C++

Microsoft Visual Studio 2010

Version 10.0.40219.1 SP1Rel

Microsoft .NET Framework

Version 4.5.50709 SP1Rel

Installed Version: Professional

Microsoft Office Developer Tools 01018-532-2002163-70484

Microsoft Office Developer Tools

Microsoft Visual Basic 2010 01018-532-2002163-70484

Microsoft Visual Basic 2010

Microsoft Visual C# 2010 01018-532-2002163-70484

Microsoft Visual C# 2010

Microsoft Visual C++ 2010 01018-532-2002163-70484

Microsoft Visual C++ 2010

Microsoft Visual F# 2010 01018-532-2002163-70484

Microsoft Visual F# 2010

Microsoft Visual Studio 2010 Team Explorer 01018-532-2002163-70484

Microsoft Visual Studio 2010 Team Explorer

Microsoft Visual Web Developer 2010 01018-532-2002163-70484

Microsoft Visual Web Developer 2010

Crystal Reports Templates for Microsoft Visual Studio 2010

Crystal Reports Templates for Microsoft Visual Studio 2010

Microsoft Visual Studio 2010 Professional - ENU Service Pack 1 (KB983509) KB983509

This service pack is for Microsoft Visual Studio 2010 Professional - ENU.

If you later install a more recent service pack, this service pack will be uninstalled automatically.

For more information, visit http://support.microsoft.com/kb/983509.

Microsoft Visual Studio 2010 SharePoint Developer Tools 10.0.40219

Microsoft Visual Studio 2010 SharePoint Developer Tools

-

I'm having the same issue. I cannot however get to the files to install manually. How do I extract them? I tried with 7zip and no go. The files described in the above text are not there. Also, am I using the wrong installer? I am installing mastercamx6-mu2-sdk-web is there a c-hook SKD???

-

Post Name : MPSUBREP

If you are having trouble with MPSubRep in version X or above not outputting the correct Z on the approach the solution is to remove v7 style contour flags.

Comment this line out or set it to zero.

rpd_typ_v7$ : 1 #Use Version 7 style contour flags?

might also want to comment this out to keep things current:

strtool_v7$ : 1 # Use Version 7 toolname? [0=Filename,1=Name,2=Path\Name] #Tool!

That will fix the issue and not drive you insane with band aids etc.

-

-

My current post creates sub-programs propely, but it puts the at end of the main program. When I load them into the contorller it does not break them up. Anyone know how to get a post to output the main file as one program and the subs as seperate programs?

Jeremy, I ran into this issue at a customers. On a Fanuc control there is a parameter that looks for the end of a program, it can either be sent to M30/M99 or the End of Tape (%). Set it to M30/M99, and the programs will be read by the machine into separate files. so much easier than sending 20 programs via rs232.

-

Hey everyone, I found the silver bullet.

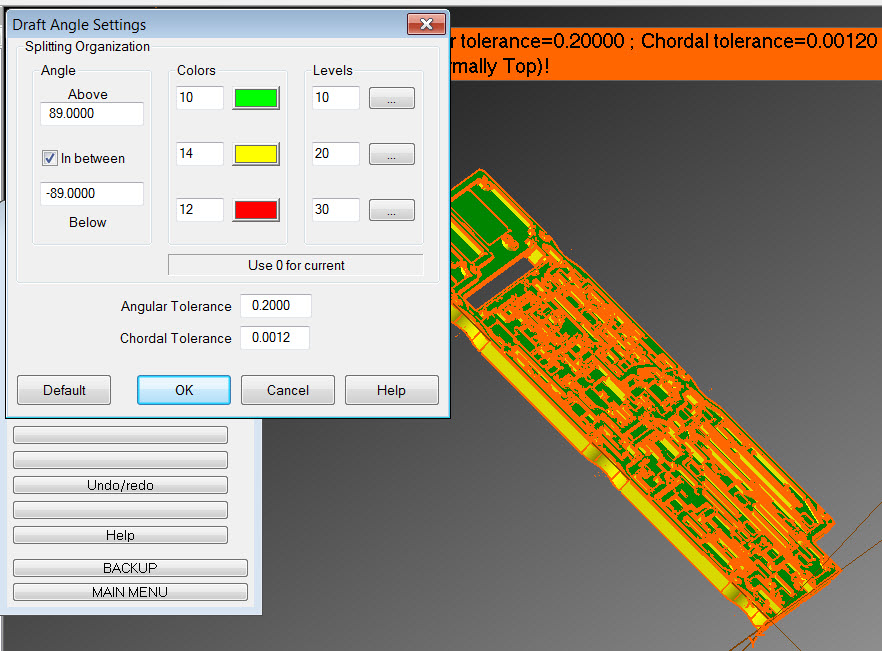

MoldPlus:

in 5 seconds you can color code the top, side and rear surfaces in one quick command:

-

I would try dynamic milling with a full depth cut at 15% step over max. Try the slowest speed on the router. Every time I see one running 20K rpm, I cringe at how much vibration they produce. I'd say keep the chip load at .0005 to start. Assuming you can do around 8K rpm, that would be 8 in/min with a 2 flt end mill. I bet that's the problem. Also make sure your tool is in there nice and short. How long is the end mill? Try to have it stick out only .25", if the flutes are crazy long buy the shortest one you can that will get the job done. Perhaps post a pic of your setup.

Also, filter the code to make sure it has as few steps as possible. Also make sure the control is in constant cutting mode and not stop mode.

-

Let me clarify, this part has many many different z depths. But thanks John, that might be a quicker way to do it.

-

Hi everyone, I have a prismatic part that has almost 6,000 surfaces and it is very difficult to work with. Since the part is totally squared off all I really need to select is the top flat surfaces in order to use 3D toolpaths to rough and finish the part. The walls of the part just increase the calculation time. Is there a way to only select 90 degree surfaces? What about changing the color of surfaces that are on different z levels? Does anyone know of a useful c-hook for doing this??

Thanks.

-

Also remember to filter your toolpath. If your toolpath is 5X smaller, then it will verify that much faster! This make a huge difference when you have a parallel toolpaths or flat toolpaths that can easily be reduced in size by replacing several linear segments with arcs. As a side bonus it will most likely run faster on the CNC machine if it is being data starved in its cut.

-

I think it's far better to just tweak your display settings than to drop several hundred or thousands on a super video card.

Why spend so much to get a 50% improvement when you can get a 1,000%+ improvement by simply tweaking your display settings. Just type in a value larger than 1 into moves/refresh on verify. A value of 2 will make it seem like your video card is 2X faster since it only works 1/2 as much. That just saved a few thousand bucks..

I generally max it out at 10,000 when verifying parts that use small tools (require stl tolerance of .001) and use fine step overs.

You can also use the turbo button for fast verify in 3X but this will not give you the same quality.

Also, we do not recommend any type of ATI card, even the FireGL. Gamer Nvida cards are ok if you just use Mastercam, if you have any other CAD software installed, they might not be 100% compatible (for example real view in Solidworks). We only recommend Nvidia Quadro FX cards.

-

MKD, silly question but is your arc geometry off by .0001" ???

-

If you are using R mode make sure you don't allow 360 deg arcs. Happens all the time.

I recommend breaking arcs at 180deg in IJK mode and 90 deg in R mode.

Might also want to run it through Cimco Edit with the purchased backplot option or a free program like NCPlot v1.3. 2.0 is better, but 1.3 has picked up many errors for me. http://www.ncplot.com/freetools.htm

-

-

Justin, throw the part on the ftp site so we can give you some suggestions.

-

But you have to admit it could make 2 rather awesome looking fat and long chips.

Benchmark 2.0

in Industrial Forum

Posted

Time: 4:16.07

i7 8700k @ 3.7 ghz

Mcam 2018

Win 10

---

It is really awesome how fast this file regenerates on relatively inexpensive hardware!