-

Posts

1,636 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Randy Morton @ Clem Industrial

-

-

one_rev : 1 #Limit rotary indexing between 0 and 360? (0 = No, 1 = Yes)

Thought I would just throw this in so all can see how, at least for me, the problem was resolved.

-

I got it all fixed up now Jay, but it was looking at it as if B370 was B10. Sadly the control (although a Fanuc) will not recognize this. And it will confuse the crap outta the operator...which might be kinda funny.

-

/Ignore. Found it in another thread (as always, right after I post this.../sigh)

-

Hey all,

Been a long time since I have been on here! O_o

Downloaded the X4 MPMaster yesterday and started doing some tuning on it. A standard horizontal program we run around 5 or 6 different WCS's (all user created). NEVER before have we had an issue with it posting above 360° but this post does. I have a B360. (= B0), B450. (= B90) and B540 (= B180).

Not sure why this is, but wondering if there is a setting where I can limit it to post only up to 359° and then reset back to 0?

Tks

-

In the tool path parameters on the thread page, change eithr the Thread Angle or Included angle to get the proper output that you require.

.gif)

HTH

-

Had looksee for that, and nothin.

Might just have to do it by hand.

Might just have to do it by hand. -

Chuck,

Mine is set the same way. I was screwing arond with the integers for over an hour this morning before I posted that. Its extremely frusterating that it works in one lathe post and the exact same thing does not in another....

-

I am getting

code:G50 S1000

T202 M41G97 S380 M03On tools with one digit. But tools with two digits I get

code:G50 S1000

T1212 M42G96 S500 M04I want my single digit code to be T0202 (for example) not T202. I realize both work just fine, but my operators are gonna change it anyways so I might as well save them some time...

Any ideas why this might be?

-

Gots me a vertical mill MD and all the trimmings, with NO rotary axis.

Have a round part, with a feature on either side identical to one another. Out of sheer lazyness I toolpath one, say Transform, Rotate, Toolplane, Ghost ops, maintain offset. Set my rotate to 1 time, 180 deg. about the TOP plane.

What do I get? An A-180.! Wth! No matter what I do, even if I take the transform and say Create New geom, and not keep the transform, it still gives me an A (although now A180, not minus) output.

Why would this be happening? I have check to make sure things like rotary/axis sub are not on.

Dunno.

-

Could also be a Misc Integers switch for this.

-

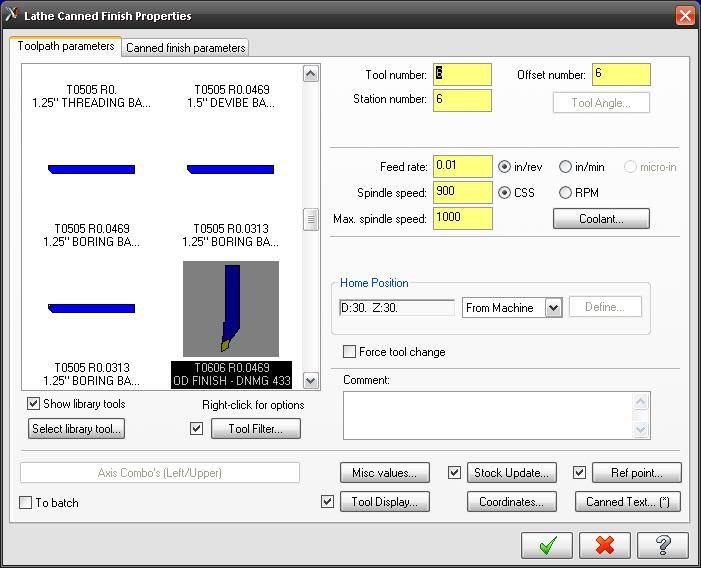

Ajmer, I am fairly confident

This instance is using a seperate tool. Even if I combine this with the roughing tool (use 1 tool) it will output in IPM.

Just outta pure giggles I switched it to IPM on that screen and it didnt change the output at all

[ 09-16-2010, 04:47 PM: Message edited by: Randy Morton @ StreamFlo Industries ]

-

My pffr was a little different then that, a couple more switches checking this and that, so I dumbed it down so it was the same as you had above and no change.

Its funny cause its only in the canned finish that I have the problem. EVERYWHERE else in post comes out in IPR. Very weird.

-

Ya, sgfeed turned my feedrate into a G98 lol. I dont think that is quite what I am looking for. But tks for trying!

-

What do you mean what post is that? Its my messed up version of the MPLMaster...by messed up, I mean re-arranged to be organized and tidy.

I will try sgfeed, tks

-

I dont want it!

code:N2 ( OD FINISH - DNMG 433 )

G50 S1000T0606 M41G96 S900 M04G0 G54 X5.25 Z1. M8Z.1G70 P100 Q110 S900 F500. <---------------G0 Z1.M9G28 U0.G0 W10.M5M30G70 callout (pread_G70)

code:pbld, n$, *scclgcode, *ng70s, *ng70e, *speed, pffr, e$

So, from what I see, the pffr callout is giving me the F500. in the above code. But I suppose the question is, since its a lathe post, why is it not converting it to IPR? The F500. actually comes from the posts Max IPM. So it might actually be ignoring what is suppose to be F.01 all together as specified in MC...?

Any one have an idea how I can reformat this to give me IPR?

Tks

-

Zoober,

My post does have that line in it. How do I mod that so its not controlled from there?

-

Why is it that by default my Misc Int/Reals are greyed out and I have to turn it on? I want it to be ON by default...

Seems random cause sometimes its on...but mostly not. How can I set this to permenantly ON?

Tks!

-

It was in pdrill_2$ telling it to auto-redirect back to pcom_movea. Weird.

Thanks for the help, Ajmer!

-

Hey all,

In meh mill post, if I select G81 drill with no custom parameters, and I have 8 holes (just example) it will only post the initial hole.

code:G90 G54 X6.037 Y1.6176 S178 M03

G43 H175 Z2.G81 Z-1.5 R.25 F4.28G80 G0 Z2.But! If I post out with a G83, I get all 8 holes. I dont know where the difference lies in the post as the two post block look virtually identical...

code:pdrill$ #Canned Drill Cycle - G81

pdrlcommonbif drl_prm1$, pdrlcst$else,[result = mr4$ + mr5$ + mr6$ + mr7$ + mr8$ + mr9$if result > 1, result = mprint("ERROR - MULTIPLE MACHINES SELECTED IN MISC REAL SECTION. PLEASE CHECK AND REPOST")pcan1, pbld, n$, *sgdrill, pdrlxy, pfzout, pcout, pindexdrl,prdrlout, [if dwell$, *dwell$], *feed, strcantext, e$ #removed *sgdrlref, 09.21.09 RDM]pcom_moveappeck$ #Canned Peck Drill Cycle - G83pdrlcommonbif drl_prm1$, pdrlcst$else,[result = mr4$ + mr5$ + mr6$ + mr7$ + mr8$ + mr9$if result > 1, result = mprint("ERROR - MULTIPLE MACHINES SELECTED IN MISC REAL SECTION. PLEASE CHECK AND REPOST")pcan1, pbld, n$, *sgdrill, pdrlxy, pfzout, pcout, pindexdrl,prdrlout, *peck1$, [if haas, *peck2$, *peckclr$], *feed, strcantext, e$ #removed *sgdrlref, 09.21.09 RDM]pcom_moveaAny ideas why this might be? tks!

-

Thanks for all the thots!

Jim, the file is the way we are doing it now, but I prefer to work smart so I can be lazy. Get it the way I want once, there forever since that is the only thing we have ever used Manual Entry for for that specific machine.

Maestro, WHY DIDNT I THINK OF THAT?!?!?! I was just editing the defaults file the other day and it didnt even don (sp?) on me...That is exactly what I needed.

Thanks Newb for the thot. I have no problem running extra stuff in my post (this post currently has 5 seperate machine definitions tied to it so you can imagine what I have had to do to the post to get it to all work...). But in this instance the easy is teh win!

Tks all!

-

Is it at all possible to hard code the text box in Manual Entry to have the same text appear ALWAYS when you select it?

Basically we have a machine, vertical mill, with a spinny pallet changer that does BHC's all day long. No, we dont need a post to do BHC's on a HAAS...but still.

Anyways, want to Manual Entry to read (example)

("code" checked off by default?)

Mxxx P1

M99

I dont remember the exact code, but its actually about 5 lines long and is tedious to type. Would like to just hit Manual Entry, OK. Done.

Any thots?

-

It may have been as far back as X2, Jim...but that already seems like so long ago I cannot be sure. But I would appreciate you looking into it for me.

Tks!

-

/agree with Rickster.

Somedays I just hate my life for using software this easy. Wish my 5 year old could use it...I suppose she will have to wait until she is 6

-

Pardon my ignorance, but how does one edit an MD while not on that MD? Maybe that right there is my problem? /confused

Control Def...

in Industrial Forum

Posted

Hey all,

Cant remember where I saw it, but I was fairly certain there is a spot in a LATHE control def that you can switch all mill commands to off? I think it was worded more like 'Post supports Mill' or something... Any ideas where it may have been I saw that?

Tks