-

Posts

737 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Rob @ Target Machine

-

-

ILoveRedSweaterVests.cfg

-

Brian,

Re: CNC 00085535

I've compared the NC code to the same paths in X4 and can't find anything wrong with the code.

It looks like this dialog is just an annoyance for now. Choose No and let er' rip. Your code should be fine.

Don't assume we won't find bad code eventually though. Always proof-read your NC.

HTH

-

Works fine for me.

Did you set the grid settings in settings-->config?

-

The Ops Mgr shuffle is back.

-

+ 1 Gcode.

Acronis Backup & Recovery 10 Advanced Workstation with Universal Restore is the version I'm using.

-

Works fine here.

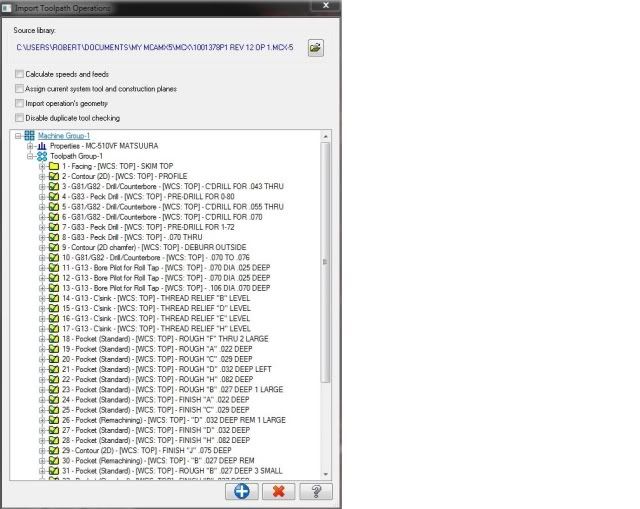

You'll have to click the folder icon at the top to navigate to your mcx folder and select mcx file type from the pull-down menu.

-

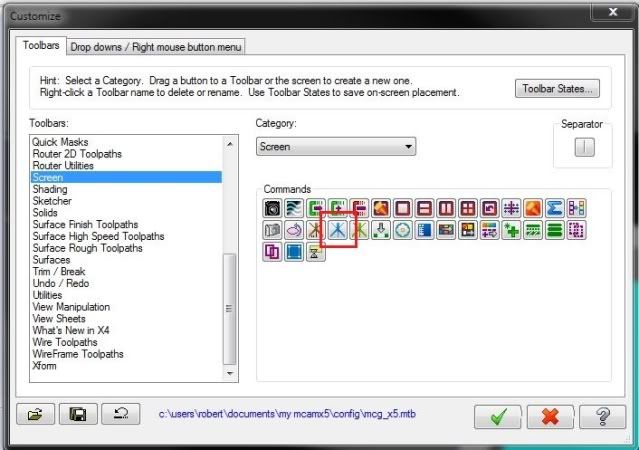

In the customize menu, under screen category, the blue icon.

-

If you're using dual monitors and your ops mgr is on the opposite screen as Mc, click any part of the ops mgr, then "E" should work fine to expand ops.

-

IIRC - This is usually referred to a PEBKAC issue...very common with Mastercam.

-

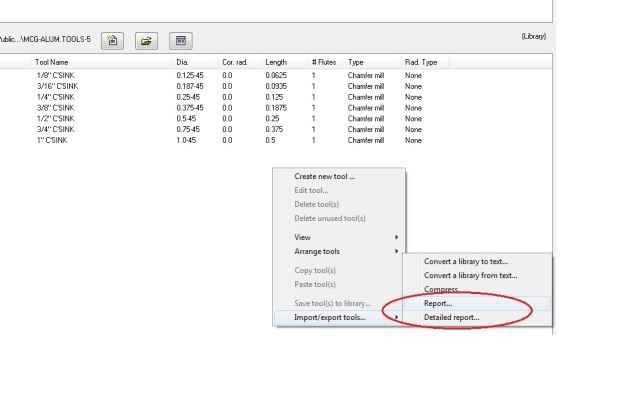

In your Tool Mgr. Import/export tools -> Report or Detailed Report

-

Hi John,

I tried to copy those codes to the post, but it didn't work.

If you're talking about "output_z : yes$ #Output Z Min and Z Max values (yes or no)", that is a switch used in the output logic.

You'll need to add all of the variable and string declarations used for depth calc and output, buffer 5 declaration, buffer 5 logic, read/write calls, output lines, etc from the Mpmaster post.

Is there any reason why you can't just use the Mpmaster post as is?

Much easier IMHO. Mpmaster X5

-

Right-click and select "Save Target As..." The file is almost 54 meg.

-

Here's the workaround:

1. Open mill default.mmd-5 and set the coolant type to X style. (uncheck support coolant using value in post-processor). Save and exit Machine def mgr.

2. Make a copy of Mill_Inch.DEFAULTS-5 on a thumb drive an rename it Mill_Inch.mcx. Open it and load the mill default.mmd-5 as the active md. Set your coolant defaults and save.

3. Take the thumb drive to another computer that doesn't have X5 installed, and rename it Mill_Inch.DEFAULTS-5.

4. Take the thumb drive back to the original computer and overwrite the existing Mill_Inch.DEFAULTS-5 file(keep a copy of the original as backup of course).

Now you should have your X style coolant defaults loaded as long as you're not using the tool's step, peck, coolant option.

HTH

-

Old forum cheers

Always glad to help.

-

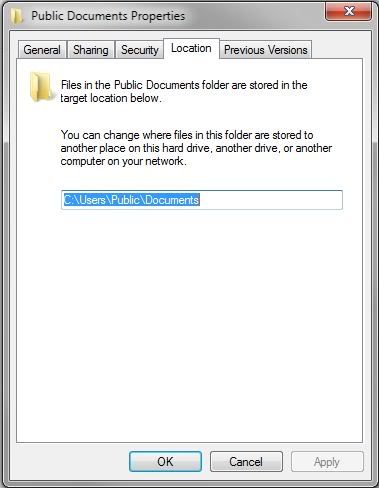

I would map the network drive first, then move the Public Documents folder in which Shared Mcx resides.

Find the Public Documents folder, right-click, choose properties, location tab, then enter the new network share path.

Edit: Jeeze gcode.....I was busy on photobucket...LOL

-

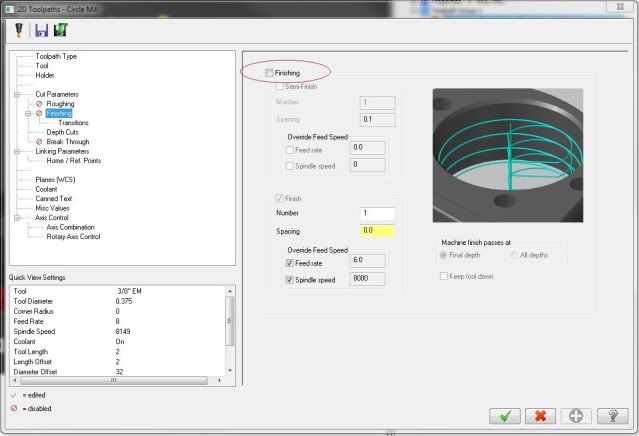

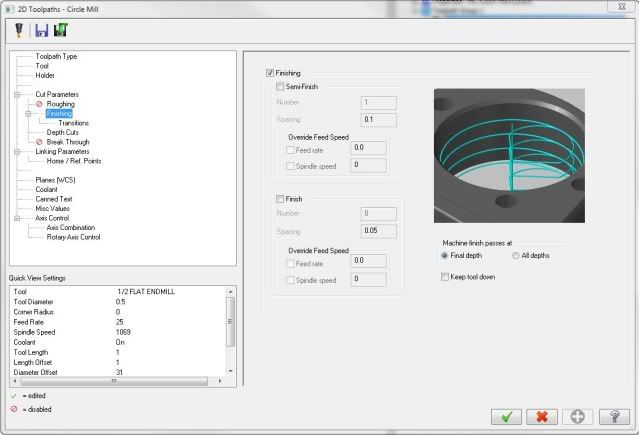

Logged as CNC 00086861

For now, here's the workaround. Set your parameters and uncheck "Finishing" last. The depth cuts should re-appear.

-

I think I remember what I had to do to stop this constant G94 output.

I'll double check in the morning, but I'm pretty sure this is what I had to do.

ptlchg_com #Tool change common blocks #Original postblock if force_output | sof, [ result = force(ipr_type,ipr_type) result = force(absinc$,absinc$) result = force(plane$,plane$) ] pcom_moveb ptlchg_com #Tool change common blocks #Edited postblock #if force_output | sof, if force_output, [ #result = force(ipr_type,ipr_type) result = force(absinc$,absinc$) result = force(plane$,plane$) ] pcom_movebThat should get rid of all but the first G94. So we'll output that in our safety line.

psof$ #Start of file for non-zero tool number ptravel pwritbuf5 pcuttype toolchng = one if ntools$ = one, [ #skip single tool outputs, stagetool must be on #stagetool = m_one !next_tool$ ] tooltotal = rbuf(4,0) #Reads total tool and null tool changes if toolcountn <= tooltotal, nexttool = rbuf(4,toolcountn) else, nexttool = first_tool$ if tool_table = 2, ppredstck if tool_table = 3, pmetastck spaces$=0 if output_z = yes$ & tcnt > 1, [ scomm_str, "OVERALL MAX - ", *z_tmax, scomm_end, e$ scomm_str, "OVERALL MIN - ", *z_tmin, scomm_end, e$ ] spaces$=sav_spc if plane$ < 0 | opcode$ = 3 | opcode$ = 16, plane$ = 0 #pbld, n$, *sgcode, *sgplane, *smetric, "G40", "G80", *sgabsinc, e$ # Comment this out # Add these two lines ipr_type = zero # <-------------- pbld, n$, *sgfeed, *sgcode, *sgplane, *smetric, "G40", "G80", *sgabsinc, e$ # <-- Safety line (set modals) sav_absinc = absinc$ absinc$ = one if wcstype <= one, #Work coordinate system [ pfbld, n$, sgabsinc, *sg28, "Z0.", e$ pfbld, n$, *sg28, "X0.", "Y0.", e$ pfbld, n$, "G92", *xh$, *yh$, *zh$, e$ ] else, [ pbld, n$, sgabsinc, *sg28, "Z0.", e$ ] absinc$ = sav_absinc sav_mi9 = mi9$ sav_workofs = workofs$ if sav_workofs < 0, sav_workofs = 0 ptlchg_com sof = 0 -

Good catch James.

-

John, I was on my way out of the shop. I'll send it in to Chris in the morning.

.gif)

-

No roughing.

John, Yeah, no finishing either. LOL

This is what will duplicate the issue. Note the state of the check boxes.

Lefty, just tick the second check box to get the DOC back.

-

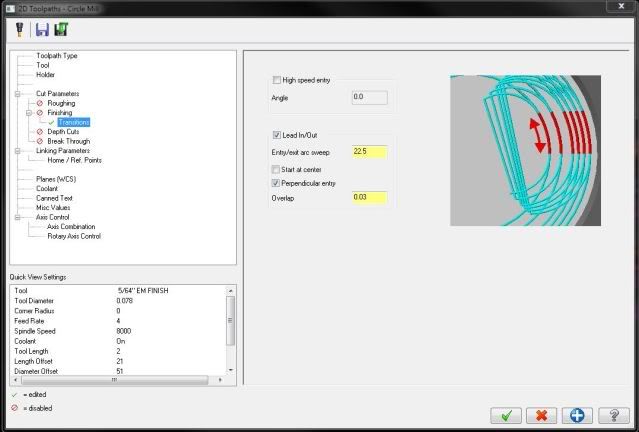

I have no option to "start at center"

Reko- Those options were move to the transitions tab under finishing.

-

This might be the thread you're looking for. Linky

-

Gcode, IIRC the problem was retract at the end of the toolpath, not the cutter comp. I haven't checked it lately.

-

As always, back up your post before making any changes.

The easiest way is to move the m5 up before scoolantx and scoolant are output.

Look for #<-- for my changes.

pretract #End of tool path, toolchange phsm_off sav_absinc = absinc$ absinc$ = one sav_coolant = coolant$ coolant$ = zero pbld, n$, *sm05, e$ #<-- Add M5 here (see below) # if nextop$ = 1003, #Uncomment this line to leave coolant on until eof unless # [ # explicitely turned off through a canned text edit if all_cool_off, [ #all coolant off with a single off code here if coolant_on, pbld, n$, *sall_cool_off, e$ coolant_on = zero ] else, [ local_int = zero coolantx = zero while local_int < 20, [ coolantx = and(2^local_int, coolant_on) local_int = local_int + one if coolantx > zero, [ coolantx = local_int pbld, n$, scoolantx, e$ ] coolantx = zero ] coolant_on = zero ] # ] #cc_pos is reset in the toolchange here cc_pos$ = zero if convert_rpd$ = one, [ gcode$ = one feed = maxfeedpm ipr_type = zero ] else, gcode$ = zero #pbld, n$, sccomp, *sm05, psub_end_mny, e$ #<-- Commented out (original code) pbld, n$, sccomp, psub_end_mny, e$ #<-- M05 moved before M09 (see above) pbld, n$, sgabsinc, sgcode, [if gcode$ = 1, sgfeed], *sg28, "Z0.", [if gcode$ = 1, feed], scoolant, e$ #if lock_codes = one & rot_on_x, pbld, n$, *sunlock, sunlockcomm, e$ #pbld, n$, *sg28, "X0.", "Y0.", protretinc, e$ #if lock_codes = one & rot_on_x & cuttype = 0, pbld, n$, *slock, slockcomm, e$ if abs(fmtrnd(cabs)) > 360 & nextop$ <> 1003 & not(index), [ if lock_codes = one, pbld, n$, *sunlock, sunlockcomm, e$ rotretflg = 1 pbld, n$, `sg28, protretinc, e$ rotretflg = 0 if lock_codes = one & cuttype = 0, pbld, n$, *slock, slockcomm, e$ ] absinc$ = sav_absinc coolant$ = sav_coolantHTH

X5 2D Dynamic Core mill

in Industrial Forum

Posted

This seems to happen when you regen multiple ops.

Regen the dynamic mill op by itself then lock it, for now....