-

Posts

737 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Rob @ Target Machine

-

-

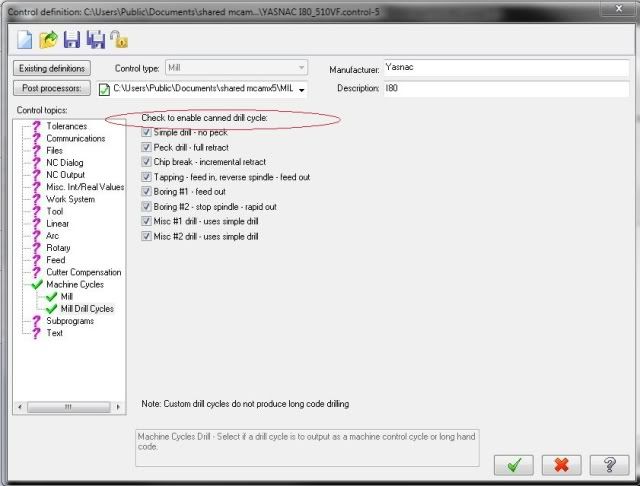

Is there a way to force point to point moves in a drill cycle rather than a canned cycle within Mastercam? Or is it all controlled by the post?

I kinda remeber doing this before, but getting old and cant remember s**t anymore.

Thanks..

In your control def. Uncheck for long code.

-

"Chief Cook and Bottlewasher"

John, did you get a promotion?

-

From page 1.

code:1. Open: C:mcamxmcxmillsamplesinchhigh speedHST-CORE-HORIZONTAL-RASTER.MCX

2. There are three operations in this file, they all have the filter set to off, with a total tolerance of .001".3. Set the Total Tolerance to .0001" on all three operations.4. Select all5. Regenerate6. Please post:Time to processlaptop/desktopCPU & speedOperation SystemRAM & RAM speed

-

Maybe a warning message will save a scare now and then.

Define the message:

code:swcswarn : "WARNING - MULTIPLE WORK OFFSETS POSTED"

Test for the condition and call the message box:

code:pwcs #G54+ coordinate setting at toolchange

if wcstype = two | wcstype > three,[sav_frc_wcs = force_wcsif sub_level$ > zero, force_wcs = zeroif sav_mi9 = 1, workofs$ = sav_workofs#if workofs$ > 0, #<----Here[result = mprint(swcswarn)] #<----to here#if workofs$ > 153,[result = mprint(swcserror)exitpost$]if workofs$ <> prv_workofs$ | (force_wcs & toolchng) | sof,[if workofs$ < 6, #G54 - G59[ #0 - 5g_wcs = workofs$ + 54*g_wcs]if (workofs$ > 5 & workofs$ < 54), # G54 J2 - G59 J9[ #6 - 53p_wcs = workofs$ - 6*sjwcs]if workofs$ > 53, # G54.1 P1[ #54 ++p_wcs = workofs$ - 53"G54.1", *p_wcs]]force_wcs = sav_frc_wcs!workofs$]HTH

-

ptooltable. There are several different output styles commented out. In your case, maybe just change the " - " to whatever you want for a delimiter. Maybe " ", "-", or "|".

Edit: Every all together now. LOL

Brad - Can you make the page a little wider?

-

Brian - As Colin said above the problem is that you chose to retain depth values when promted.

So Here's the Quick fix:

Drag an drop the drill points onto the offending operation again and choose replace then don't retain depth values.

That should fix the locked operation.

.

BTW - Welcome to the forum

-

Maybe a better way to hardcode coolant on.

If you look at pretact, 'coolant$ = zero' is what turns off the coolant.

Add 'coolant$ = one' right before scoolant is called in ptlchg_com.

From MPMASTER:

code:ptlchg_com

coolant$ = one #<--------Add this to hardcode coolant onpcan1, pbld, n$, *sgcode, sgplane, [if not(index), sgabsinc, pwcs], pfspeedout, scoolant, pfcout, strcantext, e$pretractcoolant$ = zero #<--------This should already be herepbld, n$, strcantext, scoolant, e$This will eliminate double coolant code output and allow you to use M00 before an operation at a null toolchange (mi10$).

eg. tool check, move clamps, remove slug, etc.

-

˄˄˄˄˄˄˄˄

No cat no bag. Machsim was available for X4.

.

On another note, you gotta be nuts running a 5ax machine without nc verification. There are multiple solutions to rotary moves that are handled in the post that won't show in verify and the weird stuff that happens when you get too close to a 0,0,1 vector or the center of rotation.

IMHO - Vericut would pay for itself by saving just one crash. The downtime, part, and repairs would justify the cost of one seat.

Look at Vericut limited for one machine if money's that tight. You can always upgrade later.

-

quote:Hit the enter key - this is what many forget

Or click the green ball on the ribbon bar.

Get's me all the time.

-

-

Lockheed Martin and Cobham got me buried right now ... any takers?

-

quote:What is the status of MTM for X5?

SAM Racing - Beta testers can't disclose this information.

BTW...Welcome to the forum.

-

quote:but it didn't help prdrloutSo I could still use some help to output an R value at each hole.

If your prdlout postblock looks anything like this, you're in luck.

code:prdrlout #R drill position

if absinc$ = zero, refht_a, !refht_ielse, refht_i, !refht_aJust add the force output modifier "*" to the variables that output the "R".

Like this:

code:prdrlout #R drill position

if absinc$ = zero, *refht_a, !refht_ielse, *refht_i, !refht_aHTH

-

True, you can only save geometry as a prior version, not toolpaths.

There is no workaround to this design for good reason.

For instance:

A prior version like X1 wouldn't know what to do with a Dynamic Mill toolpath from X4 because it didn't exist yet.

IMHO. If you can't get everyone to upgrade, leave them in the dust.

Dynamic Mill alone is worth it to upgrade to X4.

-

Dave,

If you double click the title bar on the Ops Mgr it will un-dock. Then you can move it to the other monitor. Double click again and it re-docks.

I guess I just like the added width of dual monitors. It frees up more space for the Mc graphics area.

BTW - You're gonna love the SpacePilot.

Best money I've ever spent.

[ 08-17-2010, 11:14 PM: Message edited by: Rob @ R & D Engineering ]

-

Jeff,

The equivalent of my build is the SolidBox Cobalt series Level 1.

I can say that I'm very happy with it and I run the benchmark in 1min 12 sec.

I wasn't too impressed with the first line of SolidBox systems, but I am impressed with what they offer now.

I'd give Mike a call at SB. I hear good things from other forum members who have purchased one of thes systems.

BTW. My next box will be a SolidBox.

My advice...Get a Cobalt Level 1 or better and ask for an Intel X25M G2 SSD instead of the 10k drives in Raid 0 or get them set up for Raid 1.

Running raid 0 is very dangerous if you're not running Acronis Backup daily like I am.

[ 08-17-2010, 10:13 PM: Message edited by: Rob @ R & D Engineering ]

-

Dave,

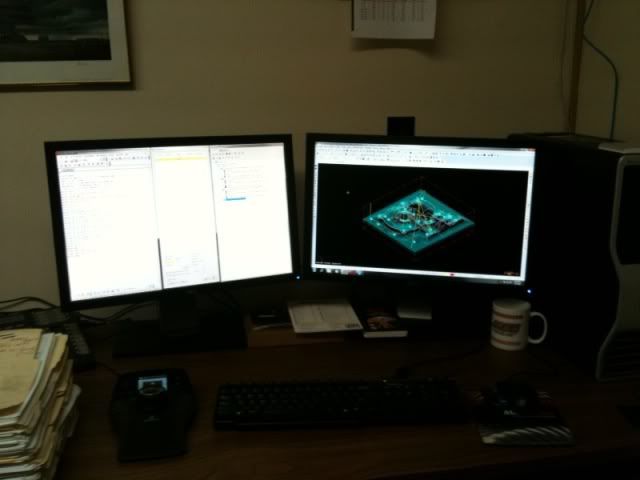

You gotta at least try out a setup like this...really, you'll like it, I swear.

Personal preferences aside, you can't beat the workflow benefits.

Here's a pic of the benchmark file on my T3500. 1min 12sec Btw.

Left monitor:Cimco/Levels Mgr/Ops Mgr

Right monitor: Mcam

-

LOFL

-

I use both.

Backplot with quick verify turned on to check against the wire or solid to check for missed corner radii.

Then verify with change tool color to see the blend areas, and of course, to verify and compare against the solid.

Why someone wouldn't use the tools in front of them is beyond me.

-

Yup, you're right.

There would be many ways around it, and if you haven't figured out how to beat it, it would be a bad idea if you're having trouble with verify crashing.

You'd be screwed.

-

That is effin' funny but....

It is conceivable that your reseller can do something like this in your post.

For instance, you could force the user to save the stl from verify with the same name as the nci file into the nci folder.

code:pcheck_for_stl

s_stl : "" # Path/Name of the stl from verifys_stl = spathnci$ + snamenci$ + ".stl"result = fexist(s_stl)if result = 1,[#do nothing - stl exists]else,exitpost$ #bail out - stl does not existNot working code here, but a just an example that shows that it wouldn't be impossible to do.

-

Ron, you nailed that one.

I can get the list in alphabetical order, but the toolbar states get all messed up.

Not worth screwing with.

-

True dat.

Advice taken.

-

Yeah, that's why I said "if" Ron. I don't have my hasp at home this weekend, so I can't give the editor a shot right now.

I use the "customize" option myself.

I just thought it might be able to be done in the editor without raising some errors.

X5 Facing Error

in Industrial Forum

Posted

I sent that one in on 11-1-2010.

Logged as CNC 00085535.