Fig sign

-

Posts

3,002 -

Joined

-

Last visited

Never

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Fig sign

-

-

The old dog does not want to learn nre tricks plain and simple.

~~~~~~~~~~~~~~~~

Huh ?

You mean the dog is me ,eh ?

-

i AM HAPPY WITH MY hAAS EXPERIENCE .

Second working place with Haases

Vm3 ,Vf3 mostly

Do not push them too hard and don`t expect them to be Matzura or Okuma .

Definetly bette rthan my former DMC- 63V machine .

-

serious parts

~~~~~~~~~~~~~~

LOL

What do you call serious .

In my mold days there were serious toolpathes and simple technology and set-up .

Now it is opposite

APprox 300 toolpathes 4 axes 3 days of programming from scratch .

And not one HSM toolpath

-

My specific of my current work is that I need to produce lots of code most of it pocket ,contour and drill .

Sometimes surface-parallel or contour

Sometimes 4-5 axes swarf or contour 5x

Lot`s of 5x positioning

And i am fast with v9

And have no free time at all .

I am working 10-12 hours every day and can not

eat out all the job

I simply have no time for playing .

Looking toward what other guys write about bugs make me not happy at all .

And drawing is slow .

Just say what you want ,it is SLOWWWW .

i NEED TO DISPERCE MY ATTENTION ALL OVER THE SCREEN WHILE IN 9 I AM FLYING .

i tried many times .

I feel discomfort

So from one side I have no urgent need for X2

I `ve installed it and use from time to time .

Still when it comes to real work I use v9

Your arguments like WE WILL LOOSE JOBS NOT

RELIVANT AT all

We are winning jobs .

It is not a software ,it is programmer that make good parts fast enough .

This is my personal point of view .

I always say what I think and say it straight in tthe eyes .

I am not a lawyer.

-

hE IS GONE ,but I am in.

And you know what drives me "uncomfortable "

Gui interface mostly .

Too many clicks disperced all over the screen

-

I will tell you and challenge any one out there that a programmer with an equal amount of training on 9 or x can get the job done in about the same time.

~~~~~~~~~~~~~~~~~~

Close to my words

I only say ver9 is faster .

Never mind ,x has a future .I only will wait to migrate in appropriate time .

In a meantime I play with it to be ready

-

stay with 2000

-

This is personal .

May be you miss solids

-

Time will show .

I will migrate in appropriate time

-

I am sure your competition will be very excited about this. You're only hurting yourself.

~~~~~~~~~~~~~~~~

Now come on !

This is kinda low ,funny argument ,designed against his boss ,maybe .

Just prove it to me .

I tried x2 in advanced things like high speed machining and I like it .

99% of my work is 2.5-3 axes stuff and 4-5 axes positioning

I do it fast

I AM CONFORTABLE .

I do not feel same comfortable in X .

I do use it for converting purposes ,though .

-

i TEnd to agree with Crazy^Millman

I never use Wcs at all ,always c-plane and tplane and WCS off

Found a couple of issues with WCS

-

What is Vista ?

-

Art is so simple to learn !

I bet it will take you no more than 2 hours

-

Thank you ,I will

If you can sent me both ,that will be great

We are buying tr160 .

-

You can import operations w/ geometry from active MC file.

~~~~~~~~~~~~~

That`s what I mean

-

no

But I built my own for tr210

Very primitive ,though ,only important boundaries

I also built all my custom fixtures

-

YES.uSE save to library and get from library

-

Do not use all caps on

Do not purcase - waste of time and money

-

No .Pete ,just pushing escape a couple of times

I dont look on the keyboard

-

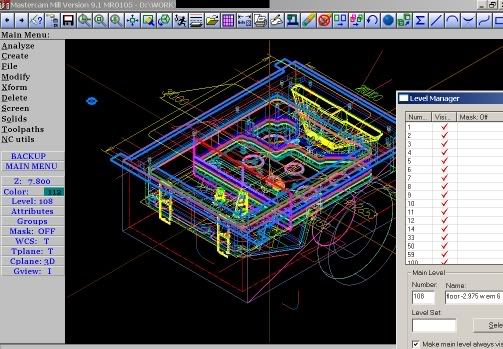

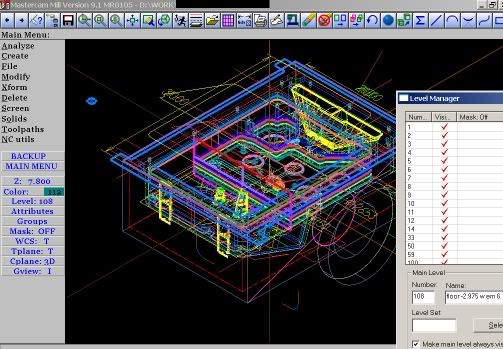

I USE X2 MOSTLY FOR CONVERTING

What I like in X2 is mostly in NC :

New toolpathes

More tools able to make undercuts

negative surface offset full support

To James

: I want you to make CLEE in ver 9 (create->line->endpoints->endpoint )

And just try same fast to do it in ver X2

Take note to ammount of clicks .

I can go on and on ....

I will fully migrate to X when I at least

would not loose speed

-

I am one of programmers .

Saying that ,I want to add that I am very fast with ver 9 and I really do not see lot`s of useful features in X2 ,that would justify my efforts .

While Being the beta tester of X , I raised ? of inrerface and speed of work .

On MHO ,it loose the race against ver 9 in design work

It may be exra fast in repeative tasks ,but I can challenge everyone of you in your custome X2 against me in my custome ver9 .

I am sure I would be faster at least 30-50 % .

And you know why .

I am old -timer and like to work with custom geometries when I really nead it .

That`s why I brake tools rarely .

When someone works with hog mill dia 10 and 120 mm height or dia 2 35 mm height in 5 axes you need to be creative

in ver9 it is an easy task

In verX2 it is ... come on ,you know yourself

Too much windows ,clicks all over the screen ,parameters here and there .

It drives me crasy .

[ 02-19-2007, 01:52 AM: Message edited by: Iskander teh Owl ]

-

Doun with your speed .dO NOT BE AFRAID TO DRASTICALLY DOUNRATE YOUR RPM

-

We milling today 316 after heat treatment With Varimill 12 mm

V=45M/MIN AND FZ=0.045 MM/MIN downstep 6 mm sidestep 1/3 -1/2 diameter WORKS GREAT and I

would use greater feed if it was more rigid setup

-

Hanita Varimill!!!!!!!!

These things eat Stainless up!

You can run a 1/2 varimill all day in this stuff.

~~~~~~~~~~~

+1000

This is my first choice in stainless in anything from 3 to 5 axes

Never ends .

Low vibration .

High feed.

Love them

Done with X

in Industrial Forum

Posted

1 click vs. 3 pecks. it's a no brainer.

~~~~~~~~~~~

That`s your personal preference .

Depends on what you are regular to .

I work with keyboard fast (with my eyes closed )

I hate programs using mouse heavily like Cimatron

(they use all the right ,middle and left clicks and all their combination L+M+R ,L+R,M+R ).

My hand is aching after the day work .

Some people like it (no need to work with keyboard !!!

I hate .

This is personal .