Elvincnc

-

Posts

62 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Elvincnc

-

-

-

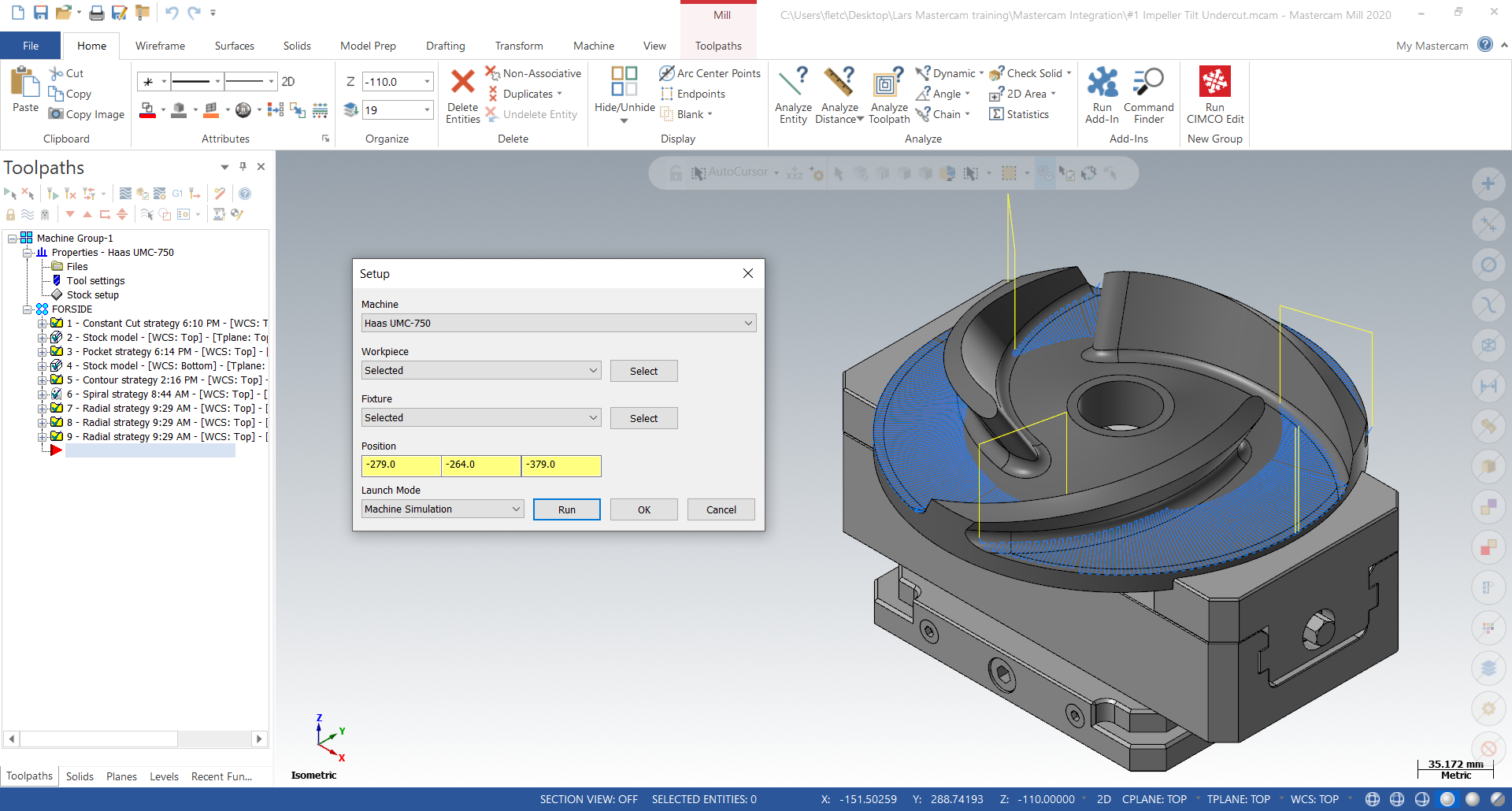

Try cimco verify https://www.cimcoverify.com/download in Version23.6.14.362 New: Turning and Mill-Turn support (Experimental). Lathe threading operations not yet supported

Now version 24.1.5.758-

1

1

-

-

IKE support Swiss type machines?

-

2 hours ago, Alex Dales said:

@JrScottI will agree with @Jake Lthat consistency across all posts does have a fair amount of advantages, and might be the best decision for many users. That being said, I am also very much against the "that's just how we've always done it" rational for decision making, so hopefully I can help to further inform your decision.

@SuperHoneyBadger did an excellent job of outlining some of the advantages we have worked hard to build into the IKE posts. I will expand on a few points, I could go on and on, but I will try my best to keep it brief.

We have developed our post generate machine simulation to mirror the motion that will occur on each line of code, as it is generated. Where this is specifically advantageous is with approaches and plane transitions, where we are able to simulate advanced controller functions like TCP and Tiled Planes. I made this video a couple years ago when these changes were introduced to show off what was now possible if your interested. Machine Simulation Improvements With Your IKE Post - YouTube

Our axis sub has been written to allow support for any machine configuration. It will run on any 5-axis configuration with a rotary table. I have even been able to post and simulate axis substitution on 6-axis machines with very little modification. Having the rotary table perform the rotations, while the universal head is fixed, but with the option to fix that universal head at infinite positions with the tool horizontal. Similar to the machine in this video, but using axis sub instead of simultaneous. Post | Feed | LinkedIn

We have a very large number of post switches available for customization, and our posts have been designed with flexibility in mind. Most customizations we do see, are already built into the post on a switch, but we are very much capable of customizing the posts as needed. We also are continually adding more switches and features into the post engine.

Despite all the great features available in the IKE posts, I think our biggest asset of IKE is the team behind it. We have a large and experienced team that is ready to customize your machine for your specific needs. We will continue to work with you until you are completely satisfied with your post, and do out best to ensure you have a positive experience throughout.

If you want to check out IKE for yourself, we have FREE IKE posts for 3/4-axis Fanuc and Haas mill available to download at this link. Free Post Processors - In-House Solutions (inhousesolutions.com)

Machine simulation works with IKE lathe postprocessor ? or DMU FD machines, I mean turning operations, without MT license

there are only different videos on youtube with milling machines, without turning operations

-

link to the program under the video

-

1

1

-

-

@Aaron Eberhard - CNC Software Part of the code is calculated in the postprocessor from the data and is output to variables for calculating wear already in the program test.NC

I think they have a motion vector, because the most difficult thing is to get a transition from a flat to a sloped surface or radius

-

1

1

-

-

13 hours ago, Thee Byte™ said:

Any (CNC or MW) multiaxis toolpath that deals with surfaces will output the tool center point, tool vector, surface contact point, surface normal at the contact point, and all of the contour flags are accurate.

MP Doc. 2020 - xsrf$, ysrf$, zsrf$ The X, Y, and Z coordinates of the tool contact point.

This data is only supported for certain multiaxis toolpaths:

Curve 5-axis (tool_op $ value 29), Swarf (tool_op $ value 48), Multisurf (tool_op $ value 110), Flow (tool_op $ value 45), Port (tool_op $ value 112)Surface normal vector (p_svec$, q_svec$, r_svec$). These are used for 3-axis cutter compensation. They are the surface normal at the current tool position with NCI Gcode 11 data.-

1

1

-

-

@Aaron Eberhard - CNC Software What tool path(5 axis) support contact point, surface vector. The more data we have, the more opportunities

Some Nx users are able to output 3D tool compensation for different controls, having a macro language cnc

-

1

1

-

-

fs2 6 3 0 3 0l #Integer, force three leading

fmt "T" 6 t$ #Tool number

-

Mill-turn supports milling machines such as DMG monoBLOCK FD, Okuma MU VAL ? single platform with simulation

-

Will there be a new version mpmaster and mplmaster 2021 ? or update yourself ?

-

Perhaps this is a German language installer that changes windows

-

-

On 3/5/2020 at 8:10 PM, 5th Axis CGI said:

You can use Optirough like 2D and get the benefit of stock models. I will make flat boundary surface of 2D shapes I want to cut with Optirough and then make the same boundary I would and then I am done.

You can show how to do it as an example, I really want to understand it

-

-

1

1

-

-

-

I also have a question, postprocessors are taken from the library renishaw or write in cnc software?

https://resources.renishaw.com/search?terms=post+processor&lang=en&div=&pur=&tab=dld

-

Where can I find dxf or stp files for the Korloy tools? I could not find on their website

-

Horizontal hst and hybrid hst (flats only) still do not know how to mill open zones (open pockets) always makes processing like a pocket from the inside.

-

-

Is there a way to find out the next vector (p_svec$ q_svec$ r_svec$) ?

-

-

-

? There are ideas for formulas

? There are ideas for formulas

MachSim, CAMplete, Vericut // Cimco Probing, Productivity+

in Industrial Forum

Posted