-

Posts

500 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Surface

-

-

There were some good tips to reduce processing time in the "tech_tips" section of the forum.

I am running a 700 mhz processer. Changing a few of the settings sugested in that post has saved me hours

-

I think 1.414 (root 2) is the ratio of the hypotenuse of a 45-degree triangle.

Similarly the ratio of the sides of 30-degree triangle is 1, 2, root 3.

Has anyone used this old technique for cutting a radius with a fly cutter?

Sin (tilt-head angle)=cutter_radius / desired_radius

-

Is it acually the pitch or the threads-per-inch that you are looking for? The equivalent TPI is 31.7

-

I did something similar back in V5 or V6. Unlike the operations manager in newer versions, the older NCI method would show "contour, contour, contour....." While the new format shows a single operation with associative parameters and geometry.

Then, I could change a single parameter of the one contour, but now it outputs that variable for the series of operations.

I overcame the problem by having only one cut depth or one piece of geometry associated with the variable that I wish to output.

But I am also curious if there is some way to initialize that variable, in the post, until it is picked up by another operation.

-

A friend and customer of mine often purchase parts from overseas because American companies often cannot compete. I often thought this was B/S. I mean, I keep up to date with technology, I keep my expenses to minimum and I take a lot of pride in what I do.

On a recent trip to Vietnam, he sent me this photo of one of my competitors.

That’s a lathe on the left, but notice the coffee table and couch behind it. That’s the living room! and the stairs behind it up to the bedroom.

How can we compete

-

I think there is a 30 day free trial of camtasia available at http://www.techsmith.com.

That may do what you are looking for

-

I need to take off from work early today to do some shopping for the usual flowers, candy and provide a romantic dinner for my wife.

How did this holiday become so convoluted?

The roots of St. Valentine's Day lie in the ancient Roman festival of Lupercalia, which was celebrated on Feb. 15. For 800 years the Romans had dedicated this day to the god Lupercus. On Lupercalia, a young man would draw the name of a young woman in a lottery and would then keep the woman as a sexual companion for the year.

Pope Gelasius I was, understandably, less than thrilled with this custom. So he changed the lottery to have both young men and women draw the names of saints whom they would then emulate for the year (a change that no doubt disappointed a few young men). Instead of Lupercus, the patron of the feast became Valentine. For Roman men, the day continued to be an occasion to seek the affections of women, and it became a tradition to give out handwritten messages of admiration that included Valentine's name.

Is anyone in favor of returning to the origions of this once great holiday?

-

I suppose you can feed in at 98% and out at 102%, but I have always fed both ways at 95% with good success. My post spits it out that way by:

ptapmatic # calculate tapmatic feedrate

tpi = peck1

tapmaticfr = (ss/tpi)*.95

*tapmaticfr

One aspect of your code which may be causing some trouble is the omition of M49, which on my machine, disables the feed and rpm over-ride pots.

-

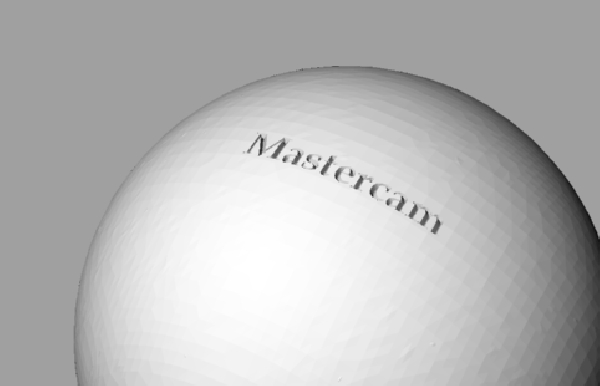

The engrave module is really nice. It forms closed contours into a 3-axis contour, with an engraving tool, so that the letters don't look so 2 dimensional. It has all the features one would expect from MC, depth cuts, depth control, and pocket routine....

Like lots of things, once you have access to it, you don't know how you lived without it.

-

And while we are on the subject, open contours are a pain to find when using the engrave modual. I wish there were a way to change color/level of open contours.

-

Jeremy,

I'm guessing that you are chaining via a window. I do quite a bit of engraving and the only way that I have found to do it is to either manually chain the entites or a faster method is to reverse/reorder by the operations-manager geometry dialog box. Although the latter method sometimes bogs down my computer when several hundred chains are involved. In that case, I chain as two separate operations.

I wish there was a more reliable method as well. I have thrown away some good parts because I did not catch a reversed chain in time.

good luck

-

look in the post for peof (end of file) and erase the unwanted line. Remember to save your post before making any changes

-

Happy Day. I finally figured out how to engrave on a surface. Thanks Jay for all of your help.

The anwser was to engrave in a flat plane. Then project the NCI with a tool of nominal diameter (.001) Save the backplot geometry and 3D contour with the engraving tool.

-

Scott,

I machined the model 7 percent larger and gave some of the parts to the foundry. They are going to make some sample castings for me and then I can measure the shrinkage.

I'm fortunate that the whole item is cosmetic and that as long as everything shrinks uniformly, everything will go together with the exeption of one part which must mate with a pre-manufactured part.

I'll let you know when I get the parts back

-

Are you sure that is the code that you desire? I have a fadal VMC and my code looks a lot different. My rigid tap code is a G84.1 The G84 is used for a floating tap holder. Another thing that is suggested is to output the spindle speed as S500.2. The .2 in this situation keeps the belts in high-range and gives a more fluid reversal.

-

High-feed really shines in rough-pocket with finish. Saves a lot of time.

-

Is the box "use tools step, peck, coolant" checked?

-

Has anyone figured out how to do this yet? I've spent the weekend trying to engrave some letters onto a sphere. 3 axis capibilities. Only one part. I know I will need to manualy rotate the part. Please Email if you would like some sample geometry.

-

I havn't tapped the stuff, but I know it can work-harden somthing horrible. As long as I maintaned a good toothload, I had good results.

Good luck

-

I've used it in the past with some good results, especially with insert cutters but prefer flood coolant for a couple reasons. Firstly, I couldn't see how it would help drilling because the drill is in the hole 90 percent of the time. Another reason is that it was kinda hard on the compressor when blowing chips around. And the biggest reason was when the hose(s) got knocked around so did all my cooling capabilities. I figure at least with flood coolant, if you hose enough onto the part, at least some will find its way onto the cutting tool.

I will be curious to see what other people have thought of this

-

Yeah, that makes sense. I have an older machine which I would program the cutter undersize .010 and use cutter comp in the control of .010 for wear. The reverse wear sounds a lot easier:)

-

I still don't quite get it. I understand the concept, but what exactly is it doing? Is it the same as reversing the cutter comp in machine? That is output a G42 instead of a G41

-

Wasn't that one of the "Bug" formats?

-

I have/use the old V5 post procceser guide. I had heard a few years ago that they were working on a new book, but have never seen it listed anywhere. Why isn't this book listed under the "books" page of the emastercam website?

Verifying a facing op

in Industrial Forum

Posted

While we are on the subject of face milling, I have a question which I have yet to figure out. Toolpaths/face; Is there any way to make the cutter climb mill? Say I have a 1 inch wide, which I want to face with a 3/4 endmill. I want to climb mill both edges to minimize the burr. Just one pass in each direction.