-

Posts

2,513 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by robk

-

-

We have quite a few El-Tool angle heads in here. Most are being used to slot and profile titanium in production environment. Some just do simple drilling. We have a few different sizes. Some are CAT50 some are Capto-C8 and some are straight shanks.

All of ours are used on Mazak Integrex machines. Great tools from our experience.

-

20 hours ago, Leon82 said:

Is it a hardened pen can you use a pulley tap?

Yes, the pin is hardened throughout @ 60-62Rc

I believe the part will be getting sent out to burn out the pin.

Thank you guys for suggestions

.gif)

-

2 hours ago, mayday said:

sinker edm

I believe this is the way we'll go...

-

1

1

-

-

8 minutes ago, GoetzInd said:

Man that's gonna be tough. I think the only option will be something custom out of a long .25 blank. Our tool grinding department could easily make something like this. I'd have them make 3 haha.

Our tool room could make them as well, but it's easier to buy something off the shelf. LOL

-

I have a broken pin that needs to be removed from a Ø.295 hole (which is on ID of part @ 38°) . The break is about 1.1" deep inside the hole. I am looking for a thread mill that will fit in there. It doesn't matter if it's single point or full profile. I just need the overall length to be able to reach in there and put in a thread to be able to use a slide hammer to remove the pin. That minimum overall length needs to be at least 3.5" in order to be able to hold the tool in shrink fit holder....

If I have a tool with Ø.150" cutting diameter and a shank of Ø.250 this gives me approximately .0025" clearance per side to mill 10-32 thread.

-

Hope you got what you needed out of the seminar Wes.

We have been using Third Wave Systems for a long time now (over 10 years) and find it very good at what it does. I would recommend getting the module to run within your CAM software as the stand alone version is nowhere near as user friendly.

-

1

1

-

-

Award Cutter has a great off the shelf selection of both ball end and flat end taper end mills. We use quite a bit of their carbide cutters in Hi-Temp alloys and are very happy with their performance.

Carbide Catalog;

http://www.awardcutter.com/Catalogs/assets/CBfullcatalog.pdf

HSS Catalog

http://www.awardcutter.com/Catalogs/assets/HSSfullcatalog.pdf

-

2

2

-

-

58 minutes ago, Mick said:

Honestly, I've never heard of the Third Wave production software. I just took a look at it. It certainly looks comprehensive. How does XChange work? Is it a module within the NX application?

Yes, you could buy a stand alone version or you could buy XChange option for a few different CAM systems. We use NX ,but it's also available for Mastercam.

-

2

2

-

-

6 minutes ago, Mick said:

Force and Optipath are great. And very capable. Their only drawback is cost. They are very expensive options. I've seen some great results though.

We only kept 1 seat of OptiPath here and I don't think anyone is using it. We're using Third Wave Systems on most projects. I really got to love it once we purchased the Third Wave XChange. So much less complicated than stand alone.

-

6 hours ago, huskermcdoogle said:

I bet we see a push for the optipath and force products. Being in the tooling industry I have always seen these as underutilized and understood tools. With some horsepower behind them they could do a lot of good out there in the field. My feeling is that someone who is well trained in how to use those tools could very easily make a living just running around optimizing regular gravy programs for shops. Couple what with a good foundation in tooling knowledge and it'd be dangerous.

I truly believe you are correct with your statements.

Cool little side story... We do not use "Force" by CGTech but were involved in beta testing it prior to CGTech purchasing it. That was back in 2010 when the software was still being developed.

We have not gone the route of "Force" because of time constraints. We have been using Third Wave Systems since around that time instead.

-

13 hours ago, YoDoug® said:

.625 IC 55 deg is not a very popular insert size. Not many people need one that big. You might be able to get a custom made.

14 hours ago, crazy^millman said:That size insert no one that I am aware of offers them.

Yeah, every major manufacturer I spoke with suggested a "special", but I would rather go off the shelf. Unfortunately I can't switch to a different insert as this is a "locked process".

Thanks guys

.gif)

-

1

1

-

-

I'm searching for a manufacturer of turning Capto holder C8 or smaller that accepts D style insert (55° Diamond-Shape) with .625 iC. Left or right hand is fine with negative clearance. I can't seem to find anything larger then .500 iC.... Technically it could be HSK as well since I can just get a Capto to HSK adapter. My current process is using a stick holder in a Big Kaiser square holder but I would rather see if there are better options.

-

-

Have you considered brushing the parts?

We do quite bit of on machine deburring and have a lot of luck using different kind of brushes for different features in Titanium. Contact a Xebec rep to help you out.

-

Xactform should have what you are looking for as a standard item.

-

3

3

-

-

We have a bunch of different brands of RAH in here. From very small to very large. I would guess we have at least 4 dozen.

The brands we have are; Alberti, Big Kaiser, Benz, Haimatec, Koma, Tecnara, ElTool.

We do use our ElTool heads to slot titanium with a 4mm end mill. It's an excellent tool.

-

1

1

-

-

3 hours ago, newbeeee said:

The stuff I mentioned is better because no mixing - you just need a flame.

I believe this may be what you are looking for. My preference is the red stick #00432

https://www.kerrdental.com/kerr-restoratives/impression-compound-

1

1

-

-

We just started too (silver only) but what a huge job and how to be sure to do it the right way...

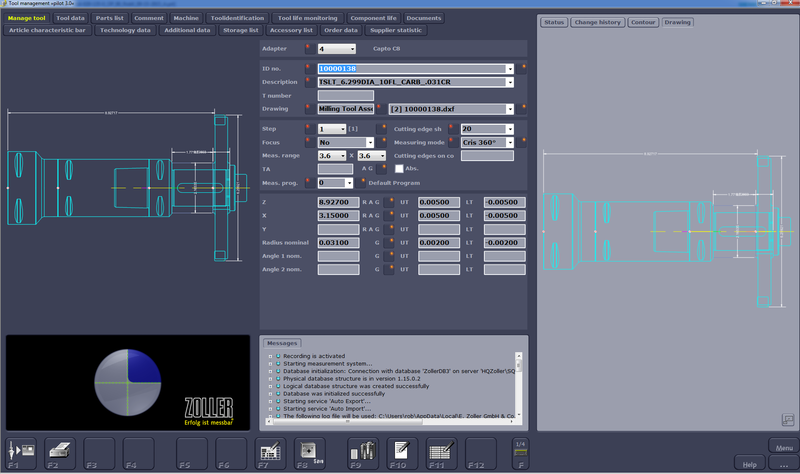

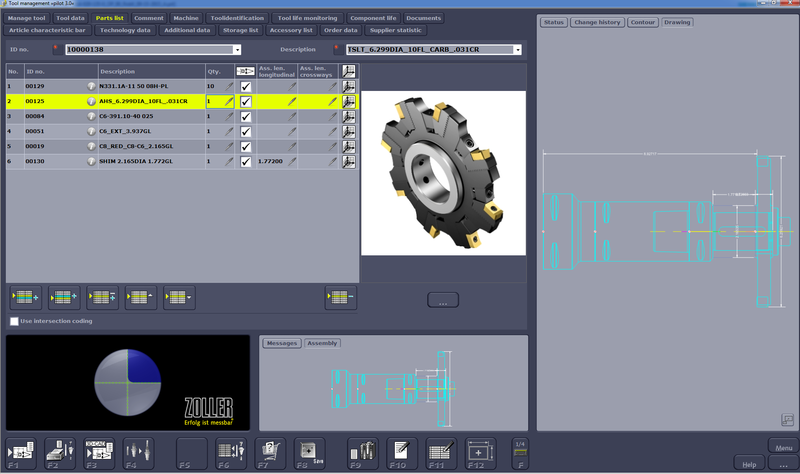

There are a lot of unforeseen issues/problems that we are running into. We are using RFID chips. Zoller and Mazak are working very hard to make the chip string work. We are almost there...

Our units are used for large mill turn machines and some of the big challenges were getting correct measurement of right angle heads as well as turning tools on different angles-- Than being able to write to different tool group #'s and managing tool life. We are also having issues with the format of DXF files that Sandvik uses. We need to "re-save" them in order to make them work.

There are other "minor annoyances", but I am really having fun with what this software could do.

-

3

3

-

-

We are in process of implementing Zoller TMS (Gold Package). Lot's of growing pains.

-

1

1

-

-

Never tried or even heard of HTC, but since names are being thrown around I would recommend Supermill.

Very high quality tools. Tool life in HTSA is great.

-

I pulled a stupid. LOL

Let's see if I get it right this time...

Left hand spiral right hand cut.

-

Hannibal is my go-to reamer as well.

We ream huge amount of titanium and inco with excellent results. For thru holes I prefer to go with right hand spiral left hand cut (*Correction per Matthew's comment below- should say Left Hand Spiral, Right Hand Cut*) and coolant between flutes.

We also use Sandvik, Fullerton, Iscar, and Komet. -

Not sure if they have metric, but Award has a very good selection.

-

Mazaks are funny with that kind of stuff. We have to add M19 codes in places that sometimes make no sense at all in order to turn spindles on (usually happens when using angle heads).

We have grinding mode options on our integrex machines, but have not used that option yet. As mentioned above this option allows you to run the machine simultaneously in milling and turning modes.

-

2

2

-

Dampened holder for endmills

in Machining, Tools, Cutting & Probing

Posted

We use a ton of dampened holders here. Most are super long dampened bars from Sandvik. It's their silent tool line. In our case they accomplished what non dampened holders couldn't do.