-

Posts

2,513 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by robk

-

-

Thanks for the input. Can not reconsider. The deal is done.

The post processor(s) have been purchased from GROB as well.

-

They brought in G350 yesterday as a loaner to get the project started. We have (15) G550's coming in and I'm just curious what is to be expected.

-

I have done a search here and G350 sounds like a lower end machine.

How about G550 with 840D control and HSK100 spindles? Any input on those?

-

( Tool Number: 84_.3125-18 TAP )( Path Name : TAP HOLES )()N16 T84 M06 T77#3901 =#4114G20 G69 G80 G40 G49 G17 G90 G94G10.9 X0 (SET RAD. MODE)G91 G28 Z0.G28 X0. Y0.G90()()/7G65 P9862 B1. T84 S3000G65 P9862 B2. T84 D84 I[.3125/2] E.010 Q.6 Z.5 S3000G4#160084=0.G4G65 P9863 T84 H-.010 S3000()()G91 G28 Z0.M200 (C AXIS CONNECTION)M108 M212 ( B AXIS UNCLAMP C AXIS UNCLAMP)G53 G90 G00 B70.G54.1 P5G00 C85.714G97 S200 M03M08G00 G90 X-.4651 Y-19.8831G68 X0. Y0. Z0. I0. J1. K0. R70. (COORDINATE ROTATION)G00 G90 G43 X-.4651 Y-19.8831 Z10. H84G00 Z.6775G84.2 X-.4651 Y-19.8831 Z-.4776 R.6724 F.055G80G00 Z10.G49 (CANCEL TLO)G69 (CANCEL COORDINATE ROTATION)G00 Z20.()()(SIDE 2)()

-

1

1

-

-

-

-

Contact Lyndex-Nikken and request a .dxf file of the tool you need. They don't have solid models of their tools, but at least you could revolve it and check it against the print.

-

I don't think it would be an issue at all. We just ran 152 holes (.4375-16UNJS) in Ti. We will run this cutter in another part.

I believe threadmilling will be a lot less expensive as well as safer than using a die. IMO, It will last at least as long as your die.

-

It seems that I can't attach an excel file.Send me your email address and I will send an excel threadmill spreadsheet.It's always good to have a backup plan.

-

Are you sure that you minor Ø is correct? Are you hitting bottom if hole is blind? I don't know what your code looks like but below is what my threadmilling spread sheet gave me for results. I selected Lakeshore Carbide threadmill #L1/4-20THRDZ Ø.180 for cutter dia. and .254 thread depth using 350sfm @ .0007 ipt . I don't use mastercam so my NX setting would be useless for you. Attached is a spread sheet for thread milling to help you out.

BTW, I have never used that brand of threadmills so I can't vouch for them.

ONEPASSINCREMENTALPROGRAMS7427 M03G91 X0 Y0 Z0G01 Z-0.2853 F25.G41 X0.0175 Y-0.0175 F10.92G03 X0.0175 Y0.0175 Z0.0063 I0 J0.0175 F4.37G03 X0 Y0 Z0.0500 I-0.0350 J0G03 X-0.0175 Y0.0175 Z0.0063 I-0.0175 J0 F6.55G01 G40 X-0.0175 Y-0.0175 F50.G00 Z0.2228ONEPASSCYCLETIME :3.02SECsTWOPASSINCREMENTALPROGRAMS7427 M03G91 X0 Y0 Z0G01 Z-0.2853 F25.G41 X0.0134 Y-0.0134 F10.92G03 X0.0134 Y0.0134 Z0.0063 I0 J0.0134 F3.35G03 X0 Y0 Z0.0500 I-0.0268 J0G03 X-0.0134 Y0.0134 Z0.0063 I-0.0134 J0 F5.03G01 G40 X-0.0134 Y-0.0134 F25.G01 Z-0.0625G41 X0.0175 Y-0.0175G03 X0.0175 Y0.0175 Z0.0063 I0 J0.0175 F4.37G03 X0 Y0 Z0.0500 I-0.0350 J0G03 X-0.0175 Y0.0175 Z0.0063 I-0.0175 J0 F6.55G01 G40 X-0.0175 Y-0.0175 F50.G00 Z0.2228TWOPASSCYCLETIME :6.04SECsTHREEPASSINCREMENTALPROGRAMS7427 M03G91 X0 Y0 Z0G01 Z-0.2853 F50.G41 X0.0134 Y-0.0134 F10.92G03 X0.0134 Y0.0134 Z0.0063 I0 J0.0134 F3.35G03 X0 Y0 Z0.0500 I-0.0269 J0G03 X-0.0134 Y0.0134 Z0.0063 I-0.0134 J0 F5.03G01 G40 X-0.0134 Y-0.0134 F25.G01 Z-0.0625G41 X0.0161 Y-0.0161G03 X0.0161 Y0.0161 Z0.0063 I0 J0.0161 F4.03G03 X0 Y0 Z0.0500 I-0.0323 J0G03 X-0.0161 Y0.0161 Z0.0063 I-0.0161 J0 F6.04G01 G40 X-0.0161 Y-0.0161 F25.G01 Z-0.0625G41 X0.0175 Y-0.0175G03 X0.0175 Y0.0175 Z0.0063 I0 J0.0175 F4.37G03 X0 Y0 Z0.0500 I-0.0350 J0G03 X-0.0175 Y0.0175 Z0.0063 I-0.0175 J0 F6.55G01 G40 X-0.0175 Y-0.0175 F50.G00 Z0.2228THREEPASSCYCLETIME :9.06SECs -

FYI, I will vouch for the ElTool coolant driven heads. We have just purchased another one for our Integrex. They work great and are a bit less expensive compared to mechanical heads. We drill and mill titanium with them without any issues.

If you feel more comfortable using mechanical heads than look into Koma Slimline. We also use these as well with very good results.

http://www.komaprecision.com/2013%20Literature/Angle%20Heads/Alberti-Slimline%2013.0%20Save.pdf

-

2

2

-

-

The setup time was very minimal (if any). We used a combination of http://www.jergensinc.com/Index.aspx and http://www.miteebite.com/ for clamping.

-

-

Rob, do you guys use Cimco DNC-Max on your Matrix controlled machines with ethernet?

No we don't Joe. Those machines are on the network.

-

Cimco DNC-Max with no issues here.

-

We use a lot of different systems and brands here and we mainly machine lots of HRSA that are very large. I am lazy in my older years so I usually get brands that have access to their CAD models in order to save me some work modeling them in vericut. Rego Fix is a system we are testing now and it seems to be working fine, but shrink fit is still my choice.

-

H.01 will check for broken condition only.

H-.01 will check for broken and pulled out condition.

But macro 9687 is for turning tools (according to my Renishaw manual) and it does not show that H value is an option for that macro.

For milling I use macro 9863. Works like a charm.

-

-

Every day's a schoolday!

I really wouldn't have thought that this was cost effective.

From my understanding the cost savings are $2-3 savings per ceramic insert. Not sure about carbide, but when you use $200K+ of tooling per month the savings are significant.

-

We have been doing this for years on round inserts only. Both carbide and ceramic. Obviously stepping down a size after regrind.

-

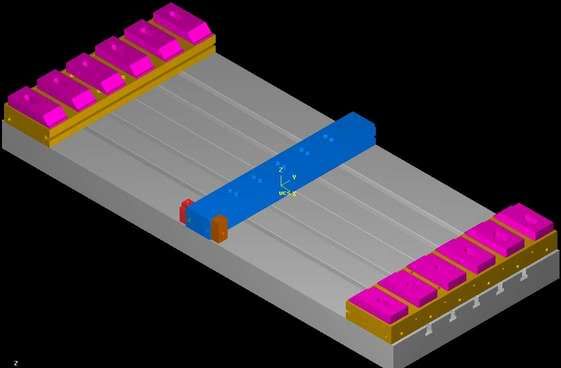

Sorry Joe. I decided to remove the pictures that I posted.

The machine is setup and will be ready to run next week as soon as they install the ball locks in the pallets.

We will be getting a lot more very large machines in the near future. Can't say anything else for now.

-

-

I belive CCAT offers that service.

-

You are more then welcome whenever you are in the area Mark.

MTConnect

in Machining, Tools, Cutting & Probing

Posted

We use Cimco MDC in here.

http://www.cimco.com/product_mdcmax_description.php3