-

Posts

2,513 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by robk

-

-

"And those were the nicest mold bases I have ever used. :cheers:"

Not sure who makes them now. New owners subbed the work and from what I heard they are nowhere near the quality they used to be.

-

Not sure about the price, but I'm sure it's not cheap...

We had a demo on Friday. It went very well. They made an inspection program to check our part on our machine in 1 day. The results were very impressive.

-

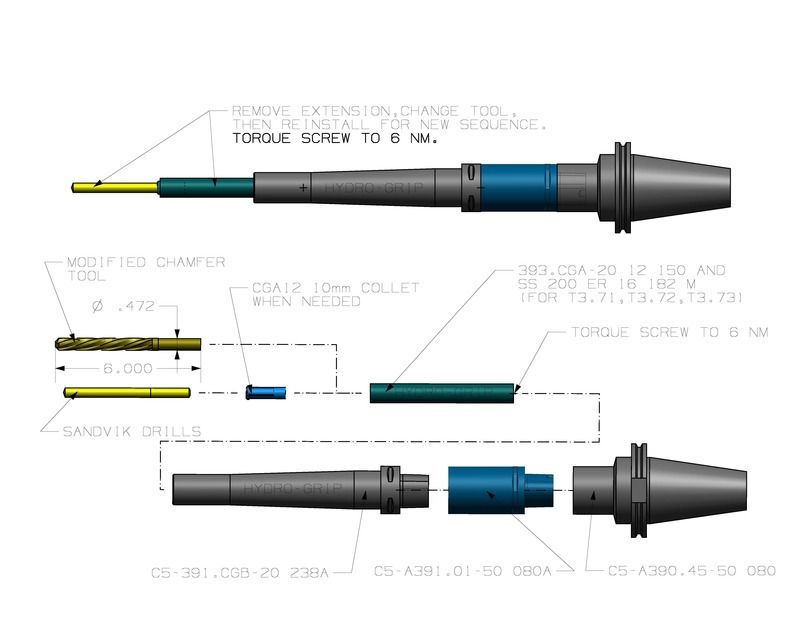

My company allows me to pick any manufacturer I want when it comes to tool selection. My goto manufacturer for high performance solid carbide drills is Walter Titex. Very happy with their selection, stock, and performance. I also love their GPS (Guided Product Search). Very easy to use.

Now in my days of moldbase and mold making we used a ton of CJT Koolcarb drills for deep drilling (waterlines) on our horizontal machines.

We used a lot of hydraulics for work holding. We also used rotary tables to reach 5 sides.

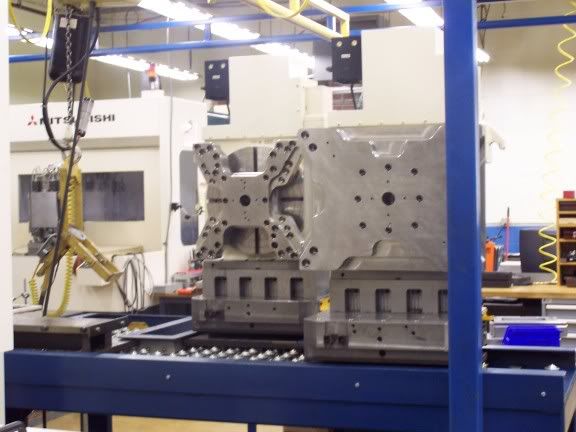

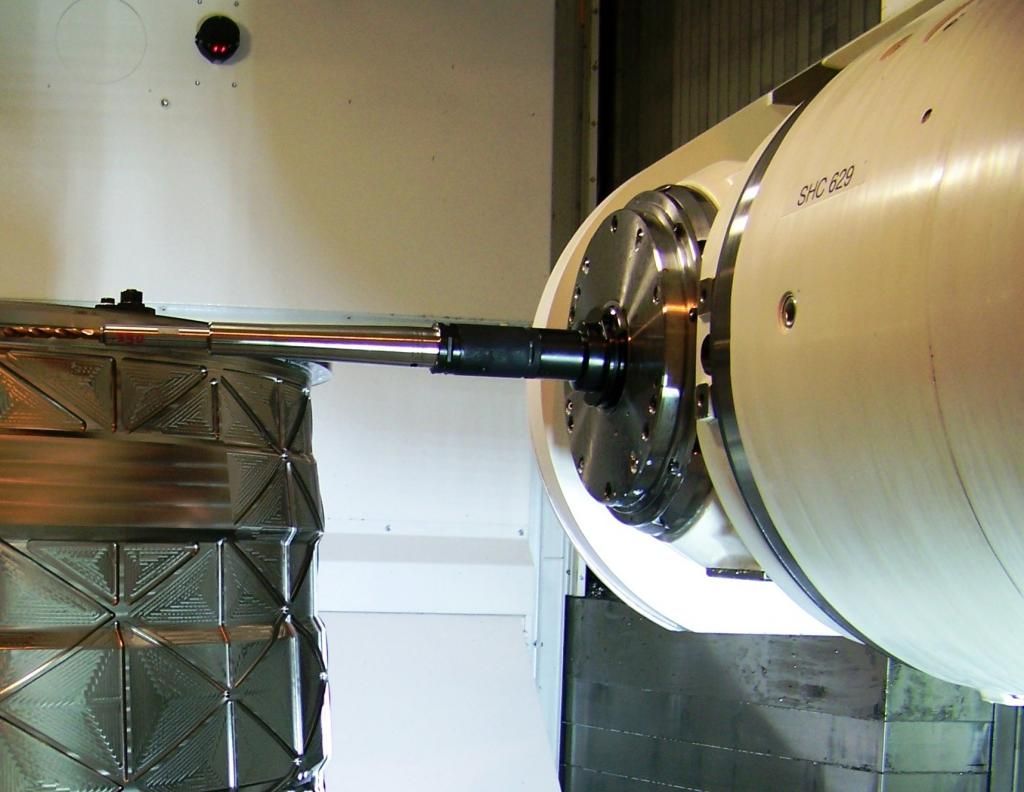

Here is a few shots of some setups when I worked for Omni and Advance Mold.

-

I'll vouch for Helical. They last forever in Titanium, and surface finish is great.

-

-

Thank for the suggestions.

Techniks and Pioneer have a 3 and 4 but no 5. Nikken has 4 and 5 but no 3. I just hate having holders from multiple vendors, different holder libraries and such. Hate to use extensions cause dealing with the setup sheets will be a PITA.

I only use one drill with a 5mm shank. I guess I could ditch it for somebody else's that has a 6mm shank, but I really like it and use it a lot.

You are wrong... Techniks has all sizes you mentioned. Check both links I posted.

-

-

You are 100% correct John.

This is just to show how much "machine operators" make @ Pratt.

-

A lot of local companies are losing a lot of good people because Pratt & Whitney is doing some serious hiring.

Nsoe was hired by Pratt & Whitney to machine engine blades in May. He earns $30 an hour plus a $3 shift differential.

-

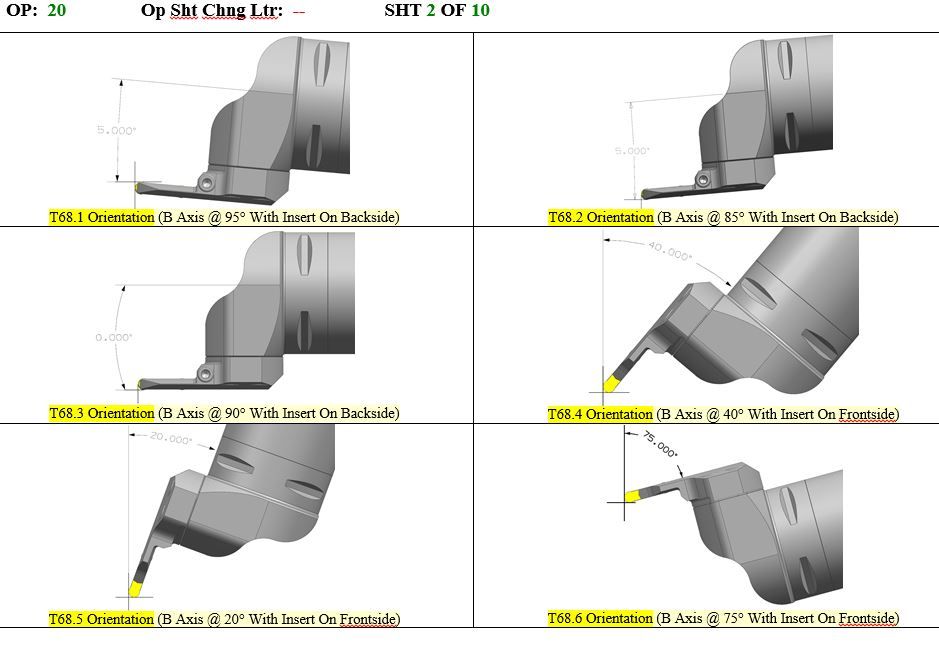

We use suffixes quite a bit here on our Integrex e-machines.A quick example would be when using turning tools;Keep in mind that every time you rotate the B axis your length A and length B will change. Therefore you need to have a different tool number, but since it is actually the "same" tool there will be no "physical" tool change. So you could use the same tool with different orientations.

-

Geez, it wasn't that long ago.

You trying to make me feel old?

Still the best mold bases I ever bought.

HA!!!

It's been 10 years since I have been with my current company.

Either way we are both 10 years older now

.gif)

-

No adjustments were ever needed. They were sitting on ground locators 1" away from tombstone. The clamps pressed them against the locators. We ran this setup lights out on standard plates from 8x8 up to 15x20 as well as some much larger sizes.

Name of the company was Omni Mold Systems.

-

Here is what "I think" I remember...

Vektek supplied all hydraulic clamping. Left side of the tombsone had bushings for locators/positive stops that were ground. They were not adjustable. The right side of the tombstone had tapped holes for locating rails that had Mitee-Bite clamps in them. There were permanent locators along the bottom of the tombstones with a couple of edge clamps.

I can't remember who built our tombstones. For roughing we would use 2500lbs and for fininshing arounf 1000lbs. Sorry, but that's the best I could do.

These were the bottom clamps.

http://www.vektek.com/pdfs/Catalog/en-us/Hydraulic/SpecialUse_EdgeClamp.pdf

Tombstone top plates.

http://www.vektek.com/pdfs/Catalog/en-us/Hydraulic/Pallet_TombstoneTopPlate.pdf

-

-

Can you print out of Cimco as shown in the view that BenK show?

-

-

Our horizontal Okuma in here uses the double hinge design. It's running a Koma setup.

-

Nothing negative about it IMO.

We have been using Techniks shrink fit CoolBLAST for quite some time.

-

1

1

-

-

That is in e-1550.

For integrex machines we currently have (1)e-1060, (1)e-1550, (3)e-1850.

We have (6)e-1250 and (1)e-1600 coming in next year and we will be ordering quite a few more in a very near future.

-

I agree, their "Silent" dampened tooling works great. You definitely get what you pay for.

-

3

3

-

-

-

Thank you for the input Daniel.

-

One of my previous employers had a stand alone Chiron. I can't remember the model, but it did do some fancy moves with the pallet LOL. The machine was scary fast too.

I never remember the machine ever being down, but that must have been about 20 years ago now.

-

Looking for opinions on Benz brand angle heads. That is one brand that I have no experience with. Currently we are using Koma, Big Kaiser, Alberti as well as ElTool. They are all good for the jobs they do. The project I am working on will require a large number of right angle heads and I want to make sure I pick the right tool. How is the quality and the service of Benz?

-

1

1

-

Blind hole manufacturing

in Industrial Forum

Posted

ALWAYS follow customer specs. Never make your own decisions.