-

Posts

2,513 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by robk

-

-

Looks alright

-

quote:Hey Rob, how much was that extra spindle?

I believe it was in the 30's... Not sure if it is a brand new unit or re-furbished though. Only got taken out of the box to make sure it was the correct unit.

-

I not only use Vericut, but we also use TMAC on our spindles, yet there is always a spare cartridge just in case something unpredictable may happen.

-

We also keep an x-tra spindle cartridge for our Integrexs' just in case (just like you-- we can't afford the down time). Both e-1060 and e-1850 take the same cartridge. We purchased ours directly from the manufacturer.

-

quote:Lots of TiAln coated carbide endmills, cut dry or w/ air blast.

I disagree... Use coolant, lots of coolant. Cobalt might work better, but you may want to try trochoidal mill method with a good quality solid carbide cutter like Kennametal HARVI, or Hanita Varimill.

I would still prefer to use ceramics, probably cheaper in the long run depending on the size of the pocket. This is my recommendation for ceramics.

1.00" Excelerator Mill from Greenleaf using Sandvik inserts (RPGN090300E grade 6060 (non whisker work better then whisker for milling)

We are limited to 10K on our spindles so we're running @ 2600 SFM and .005 IPT with DOC of .040". No problem lasting 4 minutes in the cut. If you have more RPMs' on your spindle then I would go @ least 3500sfm and maybe as far as 5000sfm.... Oh, and milling with ceramics you must run dry

-

Can you use ceramics?

-

quote:Do you one of you guys have a copy of the Mazak programming manual in pdf you would be willing to share?

Shoot me an email through my profile and I'll send you a copy of the Matrix EIA Programming Manual in .pdf format.

quote:I'm currently looking for info using G43.4 / G43.5 and how it works with the Mazak Variaxis.Did you get any answers on that yet?

-

quote:Have you used G61.1 with 5 axis toolpaths?

I don't recall ever using G61.1 with 5x paths, but I may be wrong.

I have been corrected in the past that G61.1 and G54.2 could be used together even though the manual says they can't.

quote:I'm currently looking for info using G43.4 / G43.5 and how it works with the Mazak Variaxis.I have never used G43.4/G43.5 on our Variaxis (even though we have the option), but it is the only way I fly on our integrexs'. I am interested how many people do use TCP on their Variaxis though.

quote:Inverse time has been used on this machine before but with larger parts.No small parts here.

-

No problems here. Make sure your A and C axis are not clamped if doing 5 axis work.

Here is a sample code from our Variaxis 730;

N31 T03 M6

#3901 =#4114

G80 G17 G40 G49 G94 G98 G90 G20

G0 G91 G28 Z0.0

G28 X0.0 Y0.0 C0.0

G28 A0.0

G90

M46 (A-AXIS UNCLAMP)

M43 (C-AXIS UNCLAMP)

(T3 - T03_.750_CERAMIC__ALTER_RAD)

()

(******)

(******)

M33 (LASER ON)

/7G65 P9862 B1. T3 S3000

G4

#162000=0

G4

G65 P9862 B2. D2000 I[0.7500/2] E.01 Z.375 Q.4 S3000

G4

#162000=0

G4

G65 P9863 B1. T3 H-.010 S3000 (TOOL LENGTH CHECK)

M34 (LASER OFF)

G91 G28 Z0.

G90

(******)

(******)

M1

(N31-ROUGH_IGNITER_1)

S9896 M3

()

(TOOL LEAVES 0.030" WALL MATERIAL)

(****)

(TOOL LEAVES 0.060" FLOOR MATERIAL)

()

G0 G54.1 P1 X-1.0137 Y-2.7677 A-88.2046 C96.5719

G54.2 P1

G43 Z13.531 H3

G0 G90 X-1.0137 Y-2.7677 A-88.2046 C96.5719

Z10.081

G1 Z9.9788 F89.064

X-.7065 Y-2.9828

G3 X-.5197 Y-3.0242 I.1434 J.2048

G1 G93 X-.4527 Y-3.0122 Z9.9831 A-88.1622 C96.8125 F1114.741

X-.3854 Y-3.0019 Z9.9867 A-88.1256 C97.0541 F1114.039

X-.3517 Y-2.9974 Z9.9882 A-88.1096 C97.1752 F2227.604

X-.3179 Y-2.9933 Z9.9895 A-88.095 C97.2965 F2226.848

X-.2841 Y-2.9896 Z9.9906 A-88.0818 C97.4179 F2226.388

X-.2502 Y-2.9863 Z9.9916 A-88.0702 C97.5395 F2226.121

X-.2163 Y-2.9834 Z9.9924 A-88.06 C97.6613 F2226.155

X-.1823 Y-2.9809 Z9.9931 A-88.0513 C97.7831 F2225.02

X-.1484 Y-2.9789 Z9.9936 A-88.0441 C97.9051 F2225.538

X-.1143 Y-2.9773 Z9.994 A-88.0384 C98.0271 F2224.473

X-.0463 Y-2.9753 Z9.9945 A-88.0314 C98.2714 F1112.334

X.0218 Y-2.975 A-88.0303 C98.5157 F1112.224

X.0899 Y-2.9764 Z9.9943 A-88.0352 C98.76 F1112.345

X.1239 Y-2.9777 Z9.9939 A-88.0398 C98.882 F2224.492

X.1579 Y-2.9794 Z9.9935 A-88.046 C99.0041 F2225.198

X.1918 Y-2.9816 Z9.9929 A-88.0536 C99.126 F2225.303

X.2258 Y-2.9842 Z9.9922 A-88.0627 C99.2478 F2225.168

X.2597 Y-2.9871 Z9.9914 A-88.0733 C99.3695 F2226.25

X.2936 Y-2.9905 Z9.9903 A-88.0854 C99.4911 F2226.197

X.3274 Y-2.9944 Z9.9891 A-88.0989 C99.6125 F2226.835

X.3612 Y-2.9986 Z9.9878 A-88.1139 C99.7337 F2226.832

X.4285 Y-3.0083 Z9.9845 A-88.1483 C99.9756 F1113.988

.

.

.

.

X-.7842 Y-3.0882 Z9.1726 A-88.4322 C95.622 F1140.156

X-.7187 Y-3.0698 Z9.1802 A-88.3667 C95.8574 F1139.588

X-.6528 Y-3.053 Z9.187 A-88.3069 C96.0942 F1139.251

X-.5864 Y-3.0378 Z9.193 A-88.2528 C96.3325 F1138.671

X-.5197 Y-3.0242 Z9.1983 A-88.2046 C96.5719 F1138.395

G94 X-.482 Y-3.0134 Z9.1991 F89.064

X-.4464 Y-2.9971 Z9.2015

X-.4138 Y-2.9756 Z9.2054

X-.385 Y-2.9495 Z9.2107

X-.3607 Y-2.9194 Z9.2173

X-.1523 Y-2.6154 Z9.286

Z9.4828

G0 Z13.5328

G54.2 P0

G91 G28 Z0.

G91 G28 X0. Y0. A0. C0. M05

G00 G90 G54.1 P1 X8. Y-15.

M00

()

()

-

Some of our parts are so big that they won't even fit through the doors into the inspection dpt. therefore we inspect them on the machines. Not a big deal to run a 1-2 hr. long program on a part that is on a machine for 200+ hrs. I have never had a problem yet.

-

1

1

-

-

Congratulations on the new machine. That being said I also agree with the other comments on verification software. I will not have an operator even drill a hole unless I run the code through Vericut. Not only is it part of our procedure, but it also makes me sleep better @ nights. For the most part 5 axis machines are a lot more fragile compared to a solid 3 axis mill. Last thing I would want would be for one of our machines sit idle waiting for repair because of a crash that could have been prevented in the 1st place.

-

There are a lot of standard holders that are available for downloads (I would still double-check all the dimensions). For the one's that are not available I also use the same method as described above.

-

You can not use dynamic comp (G54.2) when using G61.1

-

quote:how does NX compare in price to MC?

I really don't know Dave. Maybe somebody else could let you know the ballpark figures...

quote:I soo miss having NX to use.Did you get rid of it or did you switch a place of employment Doug?

-

quote:How do you like NX?

I Love it. I would never go back (by choice).

quote:Rob,I see you have an "EASY" button.That must be why your graphics are so kick xxxx.

-

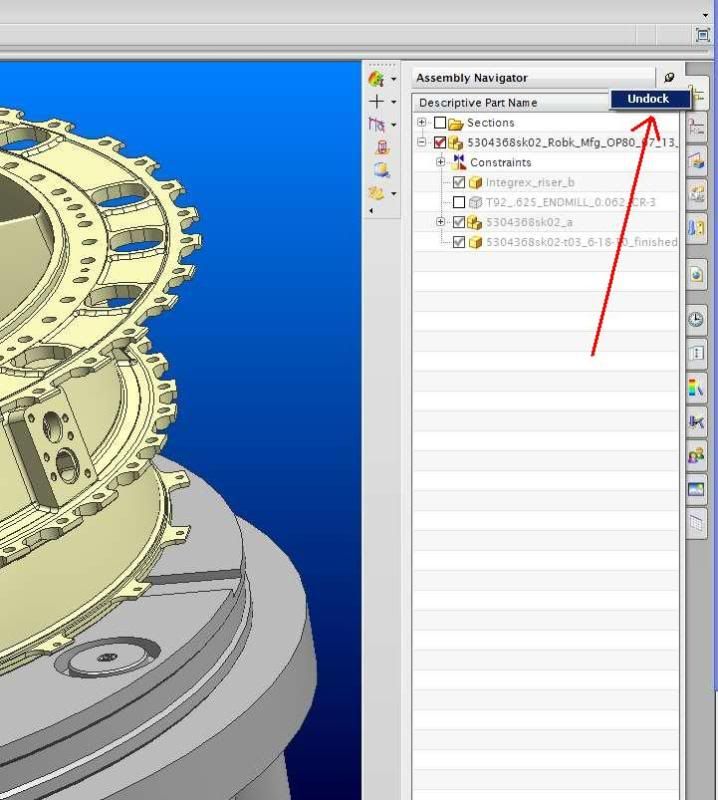

quote:how do you get the ops mangare to the second screen in UG??

Right click on any of the navigator tabs (operation, assemblies, part, machine tool, etc) and select undock.

-

quote:You can move your ops manager to a second screen in Matercam.. leaving one screenfor nothing but graphics. One you get used to all that real estate you'll never go back.You can't do that in Solidworks or any otherCad/Cam package I'm aware of.

Hmmm... Been doing it for years in UG NX...

And BTW the graphics kick xxxx.

-

-

Sorry Wes... I'll have to learn how to read. You said "directory" not file

-

quote:I dont have a print directory under c:MC_sdg in the machine so I'll create one and test it out

The print file will get created when you'll run the macro... You have to remember to delete it after you're done with the info you need because you will keep on adding to the same file.

-

quote:You can try this with #3012 Like James said or make it as a macro and call it up at the start and end of file.O1000(Sample)#100=#3012(Start of file)------------part program------------------------------------#101=#3012(End of file)#103=[#101-#100](Total time)M30

Wes, what Craig suggested above will work great on a Matrix...

To store it to a file you could just do something like this;

POPEN

DPRNT [CYCLE*TIME*IS*#103[60]*SECONDS]

PCLOS

The file will be stored in c:MC_sdgprint

-

We have a few different units in here by a few different manufacturers... We do have multiple units from Kennametal. Make sure you spend the x-tra money and purchase a more powerful unit so you could use it on HSS/cobalt tools... Keep in mind that with a weaker system you will not be able to take out an extension out of a holder. JM2C

-

Way to go Lars... Wishing you all the best @ the new job

-

No experience with it yet, but we will be using it in the very near future... One thing that I do know is that it is very high end and that it has a price tag to match.

What kind of machines??

in Machining, Tools, Cutting & Probing

Posted

Milling;

(1) Matsuura vertical MC-760V

(3) Matsuura verticals MC-1000V

(1) Tsugami horizontal MA3 with 8 pallets

(1) MH-50 Mori Seiki Horizontal

(1) MH-63 Mori Seiki Horizontal

(3) MH-80 Mori Seiki Horizontals

(1) Mazak Variaxis 730-5X

(1) Mazak Integrex e-1060

(1) Mazak Integrex e-1850

Turning;

(1) Okuma LU45

(1) Okuma LC50

(1) Johnford ST-40CX

(4) Johnford HT-40CX-2D

(1) You-Ji YV-1200ATC

Those are the machines that are in the building that I spend most of my time. There are times when I have to program machines in our other facilities. Some of those include more Mazaks, Okumas, Daewoo, Mikron, Mitsubishi, and a few Parpas, and a few more I can't think of right now.