-

Posts

1,259 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by MotorCityMinion

-

-

Thanks for the input. Glad to hear that large gap settings don't mess with the geometry.

Must have been a glitch. I switched to direct (from smooth), then regen'ed. Looked good so I reset the gap to .50 and it worked, I then reset all my surfaces that way and the tool motion, (retract) came out perfect. This also eliminated some goofy moves at the ends of the surfaces. I have both solids and surfaces in this part. Some of the solids kept giving me an invalid arc error and I ended up re-creating the surfaces, which was a bummer because the original solid surfaces seem to look more accurate (neater / tighter) than anything I create in MC.

-

I've had to increase my gap settings on several surfaces up to 6.75" in order to get the tool to stay down. Will this alter the geometry of the surfaces?

-

Mayby this will help.

http://www.emastercam.com/cgi-bin/ultimate...ic;f=1;t=030034

The coolant issues with MC is nuts. How such a low level feature can get so mucked up is beyond me. We need a Thread just for coolant topics.

-

Thanks, Got it.

-

How far from the bridge are you?

-

"With dynamic comp the distance from machine home to centre of rotation is stored in the parameters allowing you to have the origin anywhere you want it. On a machine with this feature there is no real need to programme from centre of rotation."

On large Horizontals, where part accuracy is a must (camshafts, in-line bores, etc.), we always had to warm up the machine to get accuracy within .001 tir. This was in a air conditioned shop with both new and older Mazaks. This usually involved tweaking the X axis wpc a few tenths at a time through out the day. I don't know if changing the dynamic comp in the parameters several times a day would be any quicker, maybe even more of a hassle. Heh, I've seen more than a few Operators that couldn't comprehend how to adjust for CL of rot locations and just kept getting further away from it on each succession of parts. Mayby dynamic is the way to go, locking out the parameters so the noobs don't screw up too badly.

-

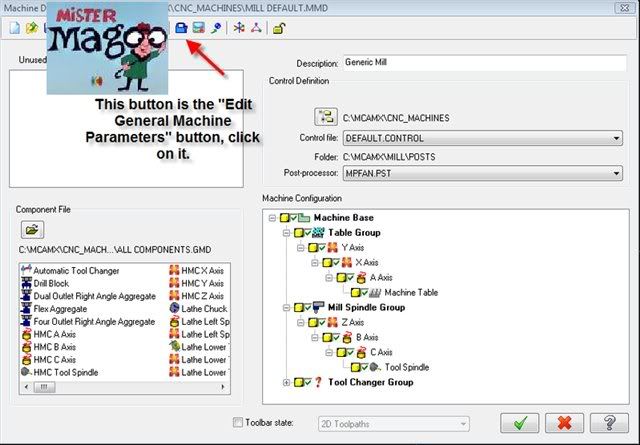

This is what I've found: Just dont know where the coolant tab is located. Mach def manager, general parameters? Sorry for being blind today.

"If you are using the version 9 style coolant (“Support coolant using coolant value in post-processor” selected in the general machine parameter’s coolant commands tab)"

Thanks to Paul Decelles @ CNC for this.

1. Make a back up of your mill_inch.defaults file

2. Rename your mill_inch.defaults to mill_inch.mcx

3. Open the mill_inch.mcx in Mastercam

4. Go in to the Machine Group properties >> edit the machine definition >> general parameters >> coolant tab >>and set it to support coolant using coolant value in post processor.

5. While your there you can go into the defaults and set them to coolant "ON"

6. Close the file

7. rename the mill_inch.mcx back to mill_inch defaults.

-

Version X from tool, using tools step peck and coolant. But I never want to touch any of those settings again, just force the coolant to come on at G43 Z, off at g28 Z in the post.

-

I am soooooo tired of messing with the coolant settings. How can I modify a mpmaster post to out put coolant for all tools at The g43 Z block, and cancle it at the g28 Z block, for ever, locked, never to be messed with again ?

-

Heh, I knew it was right in front of my face. I'm in over my head and overwhelmed on a part I shouldn't be touching and it's frustrating the hell out of me. Can't think straight. Here, the weathers good in Mich, have a cold one.

-

No subgroups , but I found it. Status bar, next to the gview tab, there is tab that switches between 2d and 3d. Duh, thanks for the help though.

-

Ok, what did I screw up now? I can't create lines in ISO view, any c-plane, at any Z value other than Z0. It's probably right in front of my face.

-

kazmir44, how much for one of them there acetylyn torch set-ups? Can ya throw in the goggles?

-

Files look good guys. Thanks for the help, MCM.

-

Yup, sure is.

-

I have to reboot to check mail, It's on a different drive. Will let ya know tomorrow.

-

-

I was there since late 2000. Never saw Watson in that area and it may have been before my time there. Oakwood Tool & Die was big in there, with multiple buildings. Watson has a shop on Pennsylvania Rd. now and a few others located around town. Thad, check out how the Rhino helped with that .igs in the other post.

-

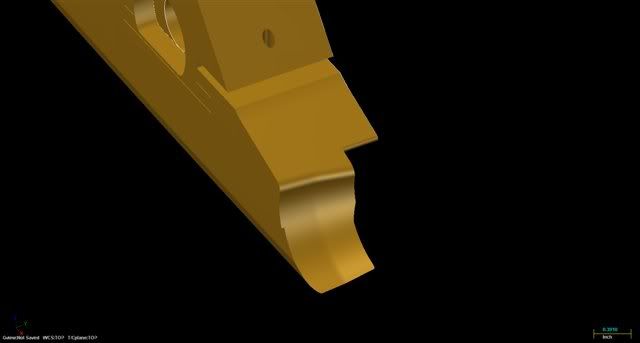

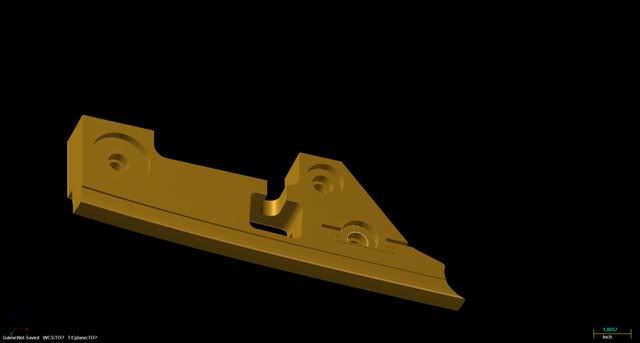

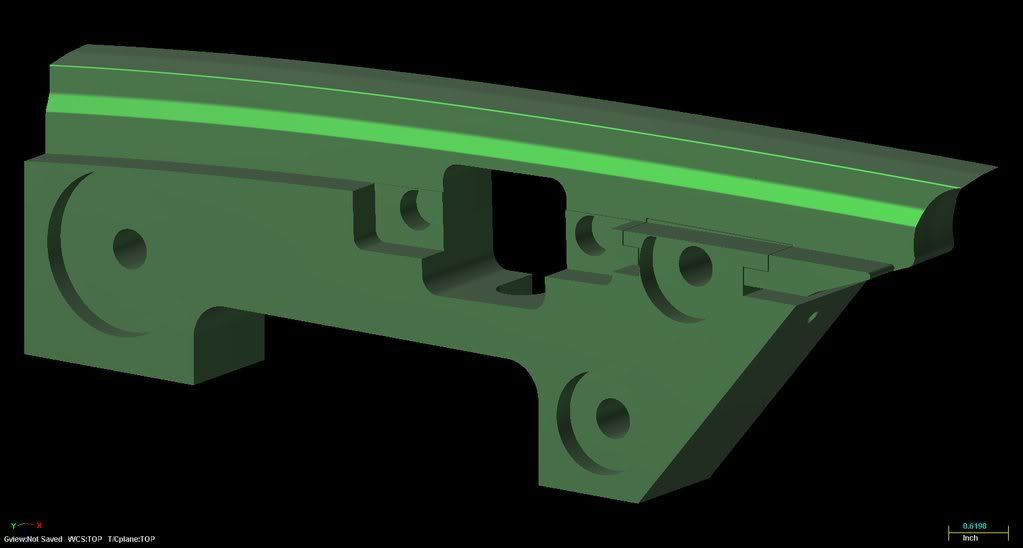

WOAH! Brought these into Rhino 1st, then saved as .3dm. Into MC they went and this is what I got. A HUGE improvement. Gotta learn Rhino now as my son helped me with these. High school cad class too, not too shabby.

-

Yup, that's the one, Universal Dr.. 7 years there. Walt Industries, didn't they make some Harley parts for awhile? I applied there once, never heard back from them. I think there dead now though. That whole industrial complex is looking grim.

-

No.

This particular customer is a middleman who specializes in re-manufacturing tools for older equipment in the aftermarket. Mostly reverse engineering. Usually he draws up his own stuff. I had the opportunity to review this drawing and recommended they stay away from it. Work in the milling dept. is slow and they took it anyway. Gotta make a right and left hand of this one and there is a smaller one that's even nastier. That's why I can take some liberties with the geometry. Even if i can get the geometry straightened out, I'm still in over my head on the surfacing. One thing at a time though.

-

will do

-

No luck so far. Turned the WF into a solid, created the curves, deleted the solid and was left with about 1/4 of the lines I needed. I might try this with Rhino and see whats happens. I'll keep messin with it in MC for a bit.

-

GMS1, I worked @ Metric right up the street from you. Also worked with Tom Nevel at 2 other shops in the past. The shop I'm currently at just got some of the Mitsubishi mills to try out on some Rex tools steels and the guys were adamant about running traditional speeds and feeds on a Tree mill. (Chickens). They never tried the 90 IPM like the rep said to start out at. I have access to a Makino S series VMC but no decent e-mill holders to use it with. Mostly shrink fit. Maybe I can talk them into buying some new holders for the Makino for a project I'm working on now.

http://www.emastercam.com/ubb/ultimatebb.p...ic;f=1;t=029938

How's business there?

Set-up sheet question

in Industrial Forum

Posted

Small enough to fit on a cell phone. XP power toys has a resizing utlity that works great for this.