-

Posts

790 -

Joined

-

Last visited

-

Days Won

117

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Del.

-

-

That's the thing about gears is that you should only need the DP, Number of teeth and Pressure angle but they always seem modified. I inputted every number you show on Esprit and can send it to you if you send me your email addy.

-

Yeah me neither..........

Now that I have a Sodick...... they are the greatest thing in the world(kinda like how some people like certain polticians or kinds of cars)

And since you said your Sodick didn't make round holes..... I have to say that round holes are way over rated........

You see I was making a....... ah...... how you say it in Kintuck........ ummmmm .... A joke......... or as foggy would would say "it's a joke Son..... It's a joke"

Well that was an older used Sodick. What kind of work will you be doing on it?

-

As a new Sodick Fanboy........ Round holes are way over rated........

Im afraid I dont understand.

-

I ran a Sodick 280L several years ago. It wouldn't burn a very round hole but we bought it used. Manual thread also.

-

Mitsubishi had too many moving parts for my liking which equals wear and replacement parts and cost. That was just my opinion and other than that they have been around a long time.

-

Del, Why open then create surfaces? when in 90% of the time you can just cut right there from the solid. Wondering why you still work this way?

I have to have solids to do that don't I ? I do work straight from the solid with Esprit. X7 is only mastercam I have with no maintenance.I only used the surfaces to get a wireframe.

-

Fanuc fan myself.

-

We have 2 Mitsubishi's. One of them is 1998 model and its still cuts all day long. They have top notch phone support for both service and tech issues.

+/- .00002

-

How do I convert sldprt files for use with mastercam?

It should open up with Mastercam and then create surfaces from a solid.

-

Wire edm in 15 minutes.

-

2

2

-

-

Thanks a bunch guys, I can see that EDM won't be an option for these parts for us right now.

I really appreciate your time and response

Have a great weekend all

Russell

The company you are doing it for must really be tight. That part is made for WEDM.

-

1

1

-

-

4-5 hours for 1 rough pass. I found the model not correctly done.

-

I hear Cimmitron is good for molds.

-

1

1

-

-

I don't see why you couldn't thread the holes before H/T but I would wire edm the slip fit holes for location.

-

-

What a waste of space.

We have 2k sq feet and 11 cnc's and a cmm and a canteen

It was more than they needed but gave them plenty of room for expansion. Personally I have never been in it. A few years back when it was a plastics plant a worker went in and killed 6 persons including self and I don't like bad Ju Ju.

-

I suspect it's brutal

We have 150k square feet of air conditioned manufacturing space

and a fleet of VTL's pulling up to 200 horse power

A man could live large on our monthly power bill

Our Production shop has 140,000 sq ft with 30 CNC machines. None as big as the ones you got though. That building is used only for production parts.

-

that demo was shot on the machine we bought

when I went to Charlotte it was still set up and they ran a pass for me

It's much more impressive in person, but not nearly as cool as the stuff

I'm doing with it 2 years later

Yeah, I know its a hell of a machine.

-

I wasn't all that impressed on the video with the 6 inch cutter on 4140.

-

I'm looking for a 1-2" digital micrometer. The Mitutoyo we have has recently **** the bed, and keeps losing its absolute positioning. Sometimes it is off by .003-.004", sometimes it seems to skip a full revolution or two. I tested my 1" gauge block, and it read .94995!

I know I can place an order with just about anyone and have it tomorrow UPS red, but I'm looking for someone within about 75 miles that stocks them. Brand doesn't necessarily matter, but price and accuracy do. I've got to have digital (mm/in conversion is important), and it has to go to half a tenth (.00005). I'm open to just about anything else.

If I can't find anything, I'll just order something, but it would be nice to find a supplier that stocks measuring tools within a reasonable driving distance.

That's why I don't like digital micrometers.

-

Well, Okuma are using it (along with other apps), so it must work for them (for Mill/Turn that is).

I've never really had a close look at Esprit, but it sure looks to be capable. If they added decent CAD then it would be a good contender I guess.

I think we are using it some on the Mill/Turn but as with any software if you don't use it everyday you never really get good at it. I had them buy me a DVD tutorial that covers a lot of stuff.

-

I hear that Esprit is expensive all the time. Interestingly, the guy selling it locally must have some deal going, as the pricing was about the same as Mastercam.

For Mill/Turn it is one of the leaders. without a doubt.

The Mill Turn is the reason we bought it. We got the Wire edm package at a good price but all together it was high. I think I'm basically the only one using it.

-

Long time Mastercam Wire user here and company bought Esprit last year so I figured I may as well learn it. Esprit Wire is great for solid models. You simply select the faces.

Esprit is feature based in that when you select features it is recognized as a hole,die,punch,open left and right etc. You can add or remove tapers,die land and also do 4 axis no core machining. Esprit is easier to add stops also. When solid geometry is brought in and faces are not able to be wired because they are not part of the wirepath Esprit allows you to split the faces so that you wire only what can actually be done. Its easy to split a solid to get a section of your part. It has a great feature called shadow where a complicated part can have a shadow cast across it to create a simple wireframe.

The cad side of Esprit sucks compared to mastercam.

If you do mostly 2D I would choose Mastercam and if using solids I would go with Esprit.

Support for Esprit is excellent. You send request for support and someone is assigned to help you and they usually send a short video to help you with your problem with results usually less than 30 minutes.

Both systems will get the job done.

-

Roughly speaking, how long would it take to wire a piece of 4140pht, 2" thick.. the cut would be 18-3/4" of continuous cutting.

The part is a C shape but with all square corners. No holes and entry from outside.

We were quoted almost 4 hours per piece. Is that a good time?

Just the wire time for me would be 3 hours plus so 4 is a fair price.

-

1

1

-

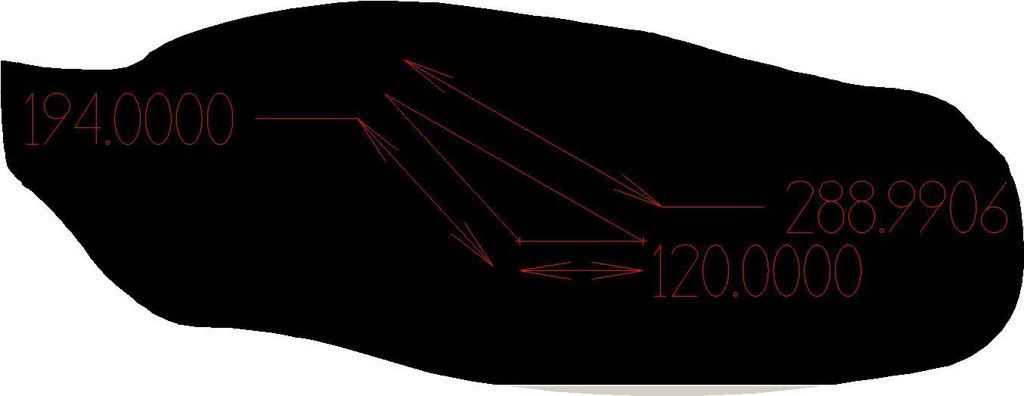

wire edm path for an involute spline

in Industrial Forum

Posted

When I inputted values it gave me a different meas over the pins by about .005 so I inputted his desired meas given on print.

I wire gears from time to time but prefer to have the mating part when I do.