-

Posts

4,188 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Store

eMastercam Wiki

Blogs

Gallery

Events

Posts posted by Thee Rickster ™

-

-

SO there are many people out there that don't see the issue

Or just a few.

.gif)

-

I have been working closely with CNC on the tool crashing issue.....been a couple days for me and no tool editing/creation crashes

I think it's fixed....I do know they want to get it into the next update whenever that happens

Has there been a first update?

I've had to go back to X7 for my difficult or large files

Why is it so hard for CNC not to just put an update every month or so with

what ever amount of bug fixes they have fixed in that time?

-

1

1

-

-

For instance, in X7-6-5-4

after an hour or so of importing tools, ops and making tools from scratch

I'll import a tool and hit properties and it wont be in the list on the tool page.

S/C/OPEN fixes it an now i can see the tool to edit it.

-

Save/Close/Open... its the long time fix for many, many Mastercam cache memory bogs.

Someday they will figure out why MC cant manage the cache to clear properly, while mastercam

is open and in use.

-

Just restart Mastercam every hour or so just like every other version, where

the cache memory gets bogged down and things slow, stop working and

many other weird behaviors.

After a restart it seems to run seemless for me.

By the time the last update they eventually release for 2017, like all the others,

it will clear up 80% of the issues.

-

No crashes today. Had it open all day.

Did a ton of complex 3-d paths and a simple flowline, (45deg surface 4"x 11/2"

.01 stepdown with a 15 deg, 3/8"Ø bullmill 0.0625 rad., also no crash.

-

See that little button save defaults? Get it like you want it and hit that button and it will save it like you want it.

haha....makes cents.

.gif)

-

1

1

-

-

In the Verify session

View then deselect "Sync Views"

Is there any way to have it stay like that permanently?

same with color loop, have to hit that one every single time i verify also.

-

Good morning

when you rotate in verify it also rotates the geometry on the MC screen

and vise versa.

Is there any way to turn off this new behavior.

I upgraded from X7 to 2017, so I don't know if this was in X8 and X9.

Thanks in advance

rick

-

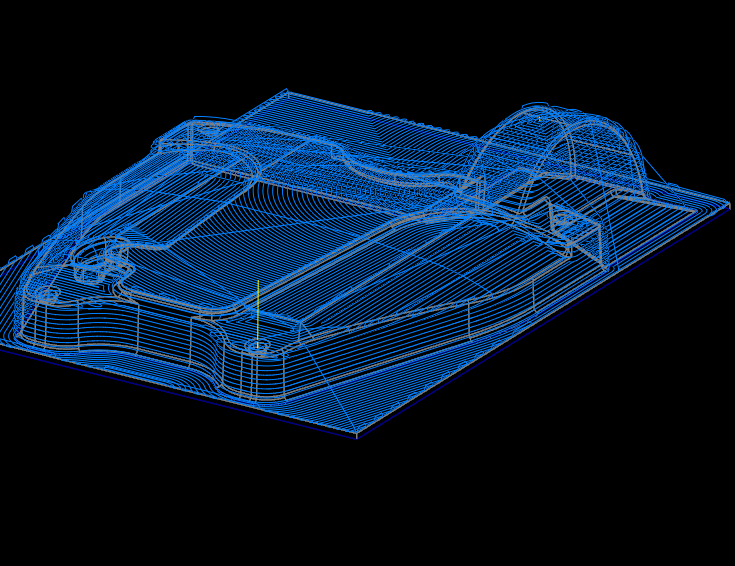

Well golly, That came out soo much better. THe material I am running is MDF, it's a constant battle to justify the need for more suited material.

You are correct I have much set to the standard defaults. Most of this is due to the lack of any official training, self taught for about 10 months now.

Many thanks, for the insight.

It'll all come together with time.

experiment with the settings and admire the differences.

cheers

-

-

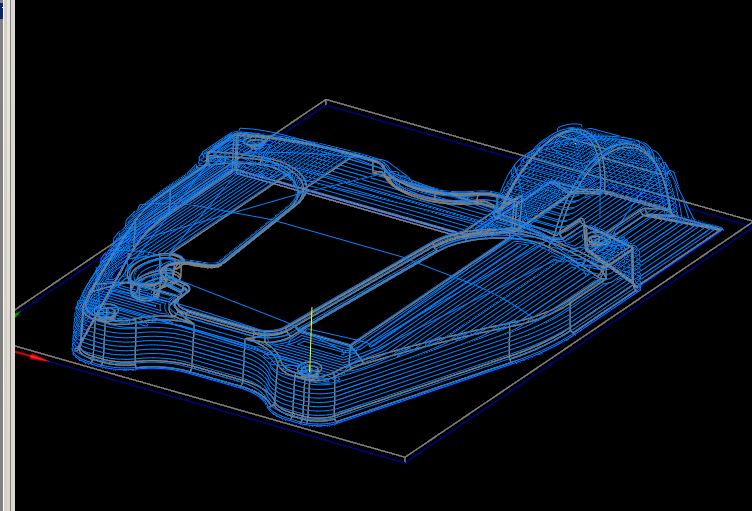

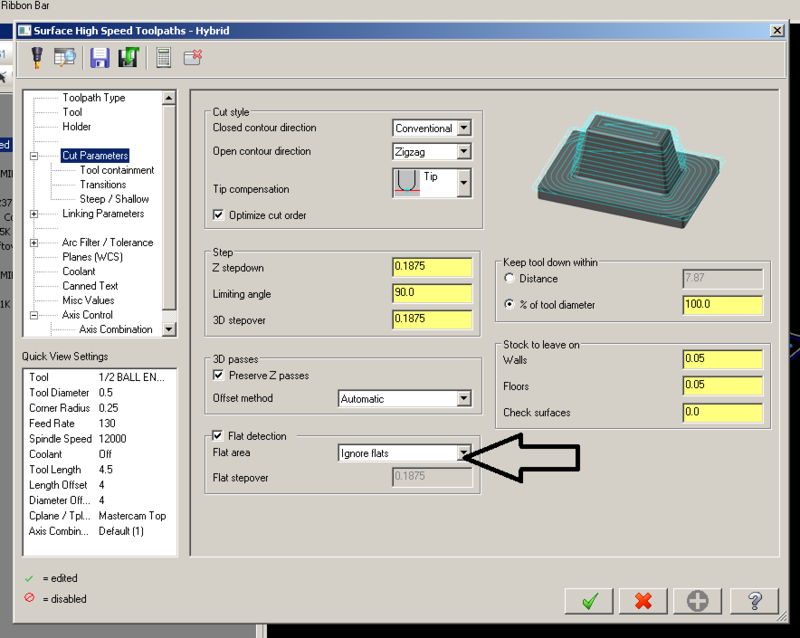

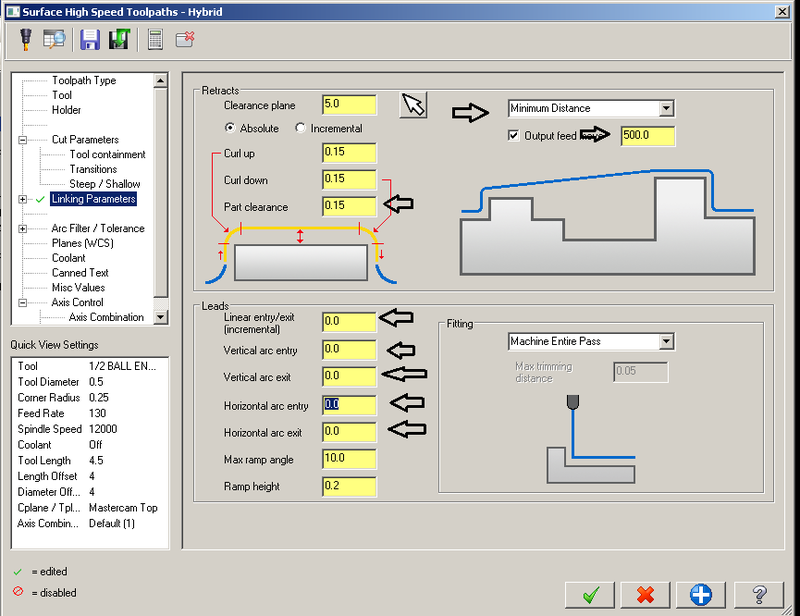

I did some quick basic changes and got this

Plus go to your transitions page and change 'skip pockets smaller than' from 0.5 to .01

You seem to be using all the defaults. There are so many things I would change pending the

material you are cutting

but it looks like you were just testing what the path can do.

.

.

-

2

2

-

-

this also happens to me but not every-time ill save about 1 out of 5, seems weird

Never thought about the merge

-

Great! I suppose next you're gonna want your own bathroom?

We already got that, its called the In-House Out-House.

-

1

1

-

-

Iv'e always wondered what your job was

its not a job, its a lifestyle!

.gif)

-

-

If this is 100% true (not doubting you Colin) then an email to all users would have been good practice IMO...

or put out updates sooner, than spending months fixing tons of stuff in one update

maybe fix a half dozen, 'easy' bugs and send an update, and so on....and so on.....

.gif)

-

2

2

-

-

Murln, 2018 is just around the corner.....

.gif)

-

Thanks gcode!

-

-

Ron that is great for one offs or production parts.

(I love easy fixes like the ones you describe)

.gif)

but i have to keep my mold designs 'up to date' in which ever software

i create them in.

i get complex engineering changes that are not just to move a hole/s.

most often my changes affect all the mold component or cause a total

recut of a mold component

i will let my CNC shop know when they finally move from X7

-

1

1

-

-

Now if you use Spaceclaim you will like the Modelprep is it just like Spaceclaim on how it does a lot of the tools and operations.

Yes, i have noticed that

.gif)

Cheers

rick

-

1

1

-

-

So you folks are just starting to use model Prep and just figured out that there is no undo. it has been promoted that it does not support undo's sense X8 when came out.

So not trying come across like an xxxx but it has sad many of times does not support undo.

I use it a lot really like it. yes the option for undo would be nice but I have figured out using how to remove most features I do if I don't like them. The more you use the more you will like it.

Well back to working. Have fun.

Jay, i went from X7, no model prep, to 2017.

just getting the 'hang of it', as i do all my designs complete in SpaceClaim

-

1

1

-

-

No, not mill/turn... but 3D surfacing, 3+2 and full 5-axis work... small auto-industry, prototype and medical industry all the way through 80,000 lb. castings for the energy industry... some files as big as 600gig+... so yeah.

Maybe I misspoke. I'm certain there are higher-end programmers than myself, doing far tougher work... but I love stock model... sometimes I have as many as 10-12 stock model's in one file... and it has worked nearly flawless for me.

i don't use as often, but so far, no complaints.

2018

in Industrial Forum

Posted

When printing in 2017, why do you have to select fit/center screen every single time?

Is there a way to have MC hit that button for you every time you go to print?

Why would it not default to fit/center?..........